When venturing into the world of custom apparel through **DTF transfer size**, understanding its importance can be a game-changer for your printing projects. Direct to Film (DTF) transfer printing has revolutionized how we approach designs on textiles, allowing for vibrant and detailed impressions on various materials. As businesses embrace this technique, determining the right transfer size becomes crucial for achieving impressive visual results and preserving print quality. This comprehensive guide covers key factors, including DTF printing guidelines and transfer size recommendations, to help you optimize your projects effectively. Ready to elevate your designs? Let’s dive into the essentials of print area calculations and discover how to maximize your success with custom DTF transfers.

In the realm of custom textile printing, choosing the appropriate **DTF transfer dimensions** is essential for harnessing the full potential of Direct to Film transfer technology. This advanced printing method facilitates high-resolution designs on diverse fabrics, providing significant flexibility for businesses and hobbyists alike. Understanding aspects such as print area specifications and the recommended sizes for various applications will empower you to make informed decisions. Additionally, considerations such as design intricacy and market trends can influence your approach to selecting the best transfer sizes. By leveraging insights on transfer dimensions and their implications, you can enhance the quality and appeal of your custom prints.

Understanding DTF Transfer Printing and Its Unique Advantages

DTF transfer printing represents a revolutionary method in the custom printing industry, specifically for textiles. By utilizing a specialized film and ink, it produces high-quality prints that can adhere to a variety of substrates, ranging from cotton to polyester blends. This versatility is one of the many reasons why DTF has gained popularity in recent years. Not only does DTF printing allow for intricate designs and vibrant colors, but it also provides a durability that rivals traditional screen printing methods.

One of the key advantages of DTF printing is its ability to produce custom DTF transfers quickly and efficiently. As more businesses adopt this technology, understanding the intricacies of DTF transfer sizes becomes essential. The ability to tailor transfer sizes based on the specific garment or application enables brands to maintain their aesthetic while achieving maximum impact. This not only enhances the final product but also contributes to overall customer satisfaction.

Key DTF Printing Guidelines for Optimal Results

When diving into DTF printing, adhering to established DTF printing guidelines is essential for achieving superior quality and striking results. One of the foremost guidelines includes maintaining optimal transfer size in relation to the print area available on the garment. As a general rule, transfers should fill the designated print area without overwhelming the garment’s design. This ensures that the final look is cohesive and impactful.

Additionally, designers must consider the material of the substrate when determining the ideal DTF transfer size. Different materials react differently to heat and pressure during the transfer process. For instance, stretchy fabrics may require a slightly reduced transfer size to prevent cracking or peeling over time. Following these guidelines helps in achieving the best results while prolonging the life of the print.

Evaluating Print Area and Transfer Size Recommendations

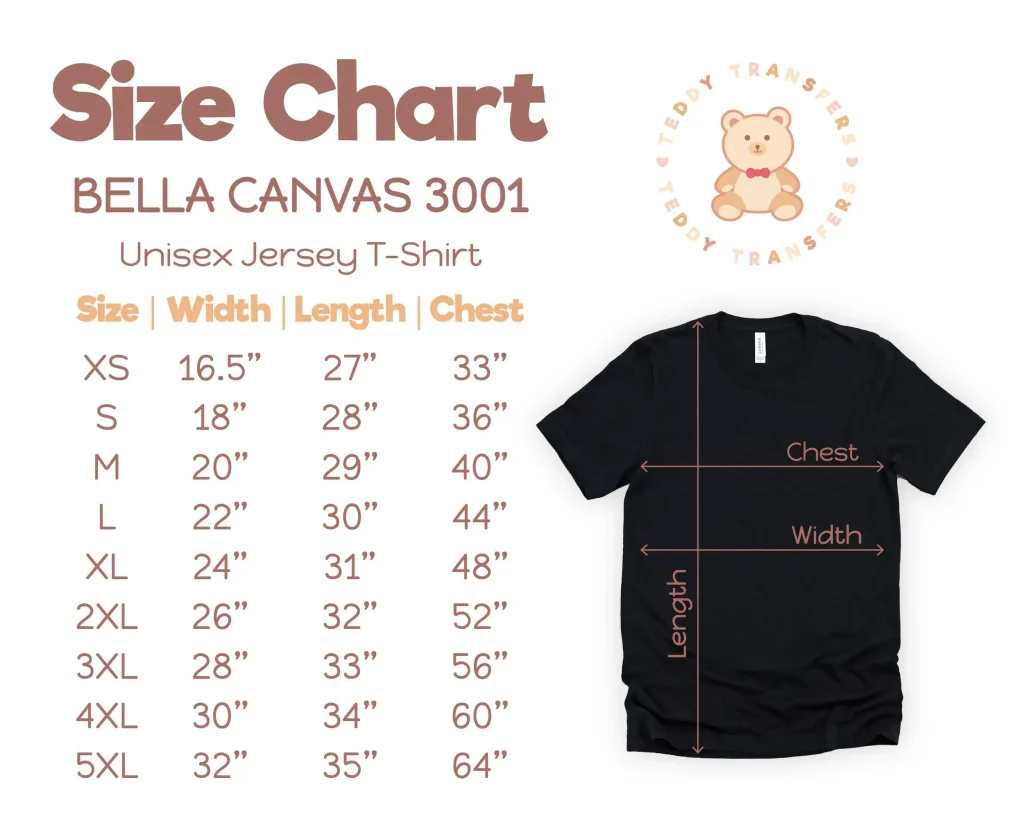

Evaluating the print area is a crucial step in determining the appropriate DTF transfer size. Each type of substrate has established dimensions that are generally accepted for printing. For example, a T-shirt typically has a print area of approximately 12″ x 16″. Size recommendations for transfers often fluctuate based on the garment type, from larger sizes for hoodies to smaller sizes for accessories like caps.

It’s also essential to keep in mind the dimensional balance of the design within the defined print area. If a design is too large, it may detract from the garment’s overall aesthetic, while a design that’s too small may not be as impactful. Therefore, understanding the transfer size recommendations in relation to garb dimensions can significantly enhance visual appeal.

Impact of Design Complexity on DTF Transfer Size

Design complexity plays a pivotal role in the determination of DTF transfer sizes. Intricate designs, with multiple colors and details, may necessitate larger transfers to ensure clarity when printed. Simplified designs, on the other hand, could benefit from more compact transfers that still command attention. Balancing size with complexity ensures that the final result is both visually appealing and practical.

Moreover, there’s a fine line between an eye-catching design and one that overwhelms the viewer. By choosing the right transfer size based on the intricacies of your designs, you can maintain the integrity and clarity of your artwork. This is particularly important for custom DTF transfers, where the focus is not only on aesthetics but also on conveying a brand message or concept effectively.

Market Trends and Their Influence on DTF Transfer Sizes

Current market trends indicate a strong preference for larger designs in custom apparel. As consumers gravitate towards bold and expressive fashion statements, businesses are adapting to this shift by employing larger DTF transfers. This not only enhances visibility but also elevates brand recognition—key components for success in a competitive landscape.

Embracing these market trends while considering transfer size can further boost a brand’s appeal. Companies that implement larger, bolder DTF transfers often find that they resonate better with target audiences, leading to increased sales. Thus, aligning transfer sizes with market preferences becomes a tactical decision that can significantly impact the success of fashion lines and promotional merchandise.

Testing and Experimentation for Ideal DTF Transfer Size

Experimentation is an invaluable aspect of fine-tuning DTF transfer sizes for optimal results. By testing different sizes on various substrates, designers can gather crucial feedback that may influence final decisions. This iterative process not only allows for adjustment based on design complexity and print area but also helps identify what resonates best with customers.

In addition, incorporating user feedback into the experimentation phase can serve as a guide for future projects. As consumer preferences evolve, adapting transfer sizes based on real-world testing ensures that final products remain competitive and appealing. Emphasizing a culture of trial and adjustment can lead to innovative solutions in the ever-changing landscape of DTF printing.

Frequently Asked Questions

What factors influence the ideal DTF transfer size for my designs?

When determining the ideal DTF transfer size, several factors come into play, including your print area specifications, design complexity, and material type. Each substrate has a recommended print area that guides transfer size, while intricate designs may require larger transfers for clarity. Additionally, understanding market trends and your printer’s capabilities will help in making informed decisions regarding transfer size.

How do I calculate the optimal print area for DTF transfer printing?

To calculate the optimal print area for DTF transfer printing, measure the designated area on your garment where the transfer will be applied. For example, T-shirts typically have a standard print area of approximately 12″ x 16″. Consider the garment type and style to ensure your DTF transfer size complements the overall design while fitting within the substrate’s specifications.

What are the best practices for custom DTF transfers in terms of size?

Best practices for custom DTF transfers involve understanding transfer size recommendations based on the design complexity and the garment’s print area. Testing different sizes for customer feedback can fine-tune your approach for optimal results. Additionally, always refer to DTF printing guidelines to align with printing capabilities, ensuring a balance between size and design quality.

Can I use larger DTF transfers for promotional merchandise effectively?

Yes, using larger DTF transfers can be effective for promotional merchandise, particularly as market trends favor eye-catching designs. Larger prints enhance brand visibility and can appeal to consumers looking for bold fashion statements. However, it’s crucial to ensure that the transfer size aligns with the garment’s print area and maintains print quality.

How does printer capability affect DTF transfer size selection?

Printer capability plays a significant role in DTF transfer size selection. High-end DTF printers can handle larger transfer sizes while maintaining print quality, whereas entry-level models may impose limitations. It’s essential to verify your printer’s specifications before finalizing your DTF transfer size to ensure quality is not compromised for size.

What are some common challenges with DTF transfer size during production?

Common challenges with DTF transfer size during production include material wastage and the risk of distortions in design. Larger transfers can lead to increased waste when design layouts are not optimized. To mitigate this, it’s important to determine the ideal transfer size based on both the design and print area calculations, ensuring efficient material use and cost effectiveness, especially for bulk orders.

| Key Factor | Description |

|---|---|

| Understanding Print Area | Identifying the recommended print area for various substrates, e.g., T-shirts typically 12″ x 16″. |

| Design Complexity and Size | Balancing design complexity with the size of the transfer for visual clarity and appeal. |

| Market Trends and Applications | Adapting transfer sizes based on current fashion trends favoring larger, bold designs. |

| Application-Specific Recommendations | Considering specific application needs (e.g., sportswear vs. work uniforms) in sizing. |

| Printer Capabilities | Understanding the limitations and specifications of your printer regarding transfer sizes. |

| Production Efficiency | Optimizing transfer sizes to reduce waste and improve cost efficiency. |

| Experimentation and Iteration | Testing various sizes can provide insights for better alignment with market preferences. |

Summary

The ideal DTF transfer size is a crucial factor that influences the overall outcome of your custom printing projects. Properly determining DTF transfer size involves understanding the print area specifications, design complexity, current market trends, application requirements, and the capabilities of your printing equipment. By harmonizing these elements, you can create visually appealing designs that stand out while maintaining quality and efficiency. Continuous experimentation and adaptation to evolving trends will further ensure your success in the dynamic arena of DTF printing.