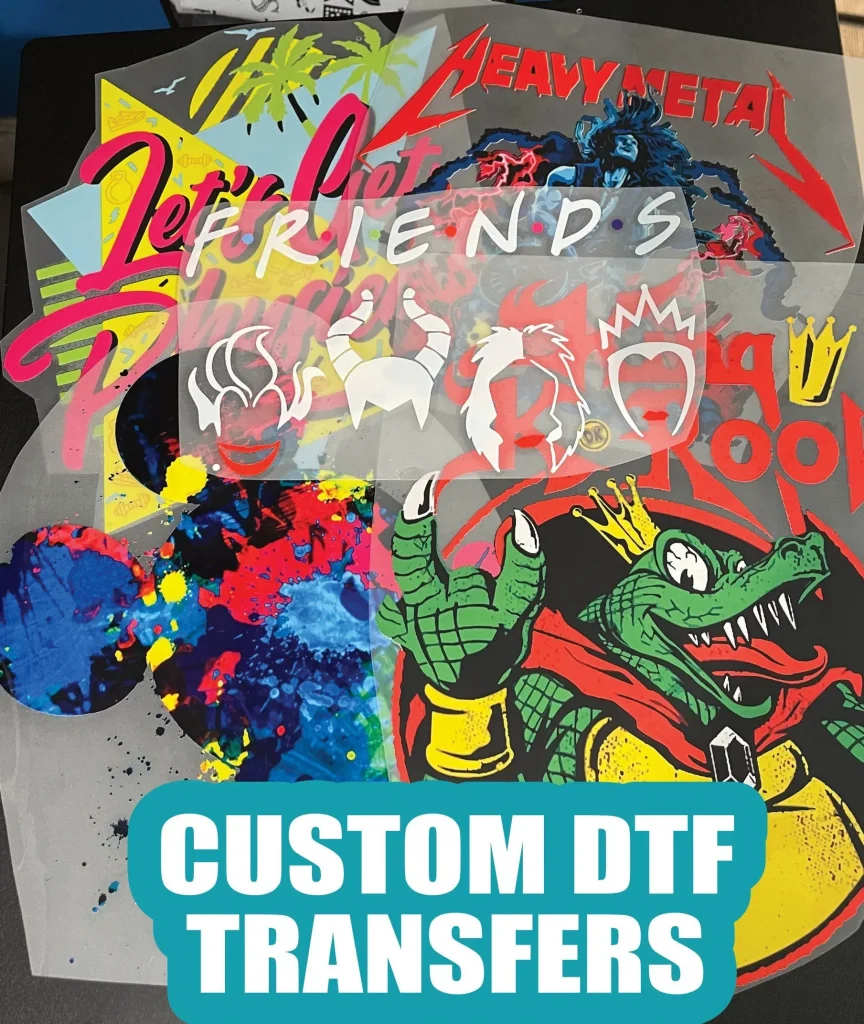

DTF Transfers, or Direct to Film transfers, are rapidly transforming the landscape of custom printing on fabrics. With the right dimensions, these transfers can enhance both the vibrancy and durability of the designs, ensuring that your creations stand out in a crowded market. Understanding the size of DTF transfers is crucial, as it dictates not only the visual impact but also the longevity of your printed designs. Whether you’re considering the best sizes for DTF applications or the ideal DTF transfers dimensions for specific fabrics, making informed choices is key to achieving high transfer quality. In this article, we’ll delve into how selecting optimal dimensions can elevate your DTF printing experience and maximize customer satisfaction.

In the realm of fabric printing, Direct to Film transfers, often abbreviated as DTF, play a pivotal role in delivering high-quality, vibrant designs. The effectiveness of these film transfers hinges on the dimensions chosen, which can greatly influence the overall appearance and durability of the final product. As decorators, understanding the nuances of transfer size is vital for ensuring that the printed designs resonate well with the intended audience. From knowing the best sizes for DTF applications to optimizing for specific fabrics, professionals in the field must navigate the technicalities of DTF printing technology. By highlighting these critical aspects, we can help you enhance your printing results and achieve outstanding DTF transfer quality.

Understanding the Importance of DTF Transfer Sizes

When it comes to DTF transfers, size plays a critical role in the overall success of a print project. The dimensions of your transfer not only dictate the visibility of the design but also directly impact durability. An appropriately sized transfer ensures better adhesion to the fabric, reducing the likelihood of peeling or fading over time. Furthermore, it provides an opportunity for intricate designs to shine without overwhelming the visual appeal of the garment. In the competitive world of apparel decoration, understanding the importance of transfer sizes is essential for creating products that command attention and satisfaction.

Additionally, the right dimensions help to maximize production efficiency. When you adhere to recommended size guidelines, you streamline the application process and reduce the chance of errors that can lead to wasted materials. This is especially true when working with fabrics that require precise application, such as polyester blends or athletic wear. By learning to appreciate the significance of DTF transfer dimensions, decorators can enhance both their craftsmanship and their business outcomes.

Best Sizes for DTF Transfers: An Overview

Choosing the best sizes for DTF transfers can vary greatly depending on the application and design intricacy. For standard apparel items like t-shirts or hoodies, sizes between 10 to 14 inches are often recommended. This range strikes a balance between visibility and practicality, allowing for ample space for designs without overcrowding the garment. When creating a layout, consider the overall proportions and where the garment will be worn to ensure it captures the desired aesthetic.

For intricate designs, such as those featuring multiple colors or finer details, it may be advantageous to adjust the size to fit within the confines of the garment more snugly. For example, a piece aimed at a younger audience may benefit from a more compact design that doesn’t overshadow the item’s style. Rather than simply scaling down, it’s essential to keep design elements visible and balanced so they maintain clarity even after the transfer process.

DTF Transfer Quality: The Impact of Dimensions

DTF transfer quality is intricately linked to dimensions, as the size influences the effectiveness of the transfer application and its final presentation on fabric. When dimensions are mismatched with fabric or design, the risk of quality degradation increases—I.e., images appearing pixelated or lacking color vibrancy. This diminishment not only affects the aesthetic appeal but also the longevity of the garment, which is particularly crucial in fashion industries where customer satisfaction hinges on perceived value.

Moreover, conventional wisdom suggests that larger transfers can sometimes undermine the integrity of the print. As mentioned in various print-focused publications, oversized DTF transfers can result in increased stretching or cracking, leading to premature wear. In contrast, adhering to precise sizing guidelines allows prints to remain intact and vibrant, ensuring that the customer experience is positive and that repeat business is derived from high-quality products.

Crafting Effective DTF Transfers: Tools and Software

To achieve excellent DTF transfers, leveraging the right tools and software is crucial in determining the correct size for your designs. Industry-standard software such as Adobe Illustrator and CorelDRAW offer precision tools for scaling images effectively while maintaining resolution quality. These programs enable designers to manipulate dimensions accurately, ensuring that your transfer aligns perfectly with the intended outcome on fabric.

In addition to traditional software tools, online resources like DTF Depot can further simplify the sizing process. This platform allows users to enter specific garment dimensions and receive tailored recommendations for transfer sizes. By integrating technology into your workflow, you can enhance your design process, resulting in more efficient and impactful DTF transfer applications.

Recent Advancements in DTF Printing Technology

The evolution of DTF printing technology has significantly influenced standard practices regarding transfer sizes. With advancements in print resolution, today’s DTF printers can now create intricate designs with alarming clarity, even at larger dimensions. This change presents exciting opportunities for decorators to experiment with previously established guidelines, encouraging bolder and more expressive designs without sacrificing quality.

Furthermore, understanding the interaction between different fabric types and DTF technology plays a pivotal role in making informed decisions about sizing. As new fabrics and blends become popular in garments, decorators must learn how these materials respond to various transfer sizes to maintain print integrity. Keeping abreast of advancements in both technology and fabric characteristics empowers designers to produce superior transfers that meet the evolving demands of the marketplace.

Practical Tips for Selecting DTF Transfer Sizes

When selecting sizes for DTF transfers, a good first step is to understand the specific fabric you are working with. Different materials, such as cotton, polyester, or blends, will react differently to the transfer application. Heavier fabrics may require more robust transfer dimensions to ensure proper adherence, while lighter fabrics could benefit from smaller sizes to avoid extra bulk. By familiarizing yourself with these nuances, you can enhance the overall quality and performance of your prints.

It’s also essential to test your sizes and designs before committing to larger orders. Conducting trials on sample pieces allows you to evaluate how well your transfers apply and wear over time. By observing the outcomes, you can make adjustments that lead to improved visual appeal and functionality. Regular test iterations are a great practice, ensuring that your production runs yield consistently high-quality results that satisfy customer expectations.

Frequently Asked Questions

What is the ideal size for DTF transfers on standard apparel?

The best sizes for DTF transfers on standard apparel, such as t-shirts and hoodies, typically range between 10 to 14 inches. This dimension optimizes visibility and ensures that the transfer stands out without compromising the garment’s integrity.

How does the size of DTF transfers affect the quality of the final product?

The size of DTF transfers significantly impacts the quality by influencing visibility, durability, and aesthetics. Properly sized transfers prevent issues like peeling and fading, ensuring a longer-lasting and visually appealing print.

What dimensions should I consider for intricate designs in DTF transfers?

For intricate designs in DTF transfers, it’s advisable to adjust the size according to the garment’s outline, focusing on clarity and detail. Smaller dimensions may enhance the overall aesthetic by minimizing excessive negative space.

Are there recommended tools for designing DTF transfer sizes?

Yes, professional design software like Adobe Illustrator and CorelDRAW are great tools for adjusting DTF transfer dimensions precisely. Additionally, online resources like DTF Depot can provide size recommendations based on garment specifics.

How does DTF printing technology influence transfer size choices?

With advancements in DTF printing technology, higher print resolutions allow for larger transfer sizes without sacrificing clarity. As printers improve, it’s essential to reevaluate size guidelines to take advantage of enhanced quality.

What should I consider when selecting DTF transfer dimensions for different fabrics?

Selecting DTF transfer dimensions requires knowing your fabric, as different materials may require adjustments in size. Heavier fabrics might need different dimensions compared to lighter ones to ensure proper adhesion and clarity.

| Key Point | Details |

|---|---|

| Significance of Size in DTF Transfers | Size influences visibility and durability of transfers, preventing issues like peeling or fading. |

| Ideal Dimensions | Standard apparel transfers should be between 10 to 14 inches for optimal效果. |

| Design Considerations | Detailed designs may require adjustments in size to avoid excessive backgrounds. |

| Tools for Sizing | Software like Adobe Illustrator and online tools can help determine ideal sizes. |

| Technology Advancements | Modern DTF technology enables larger, clearer prints—revising previous size standards. |

| Fabric Considerations | Different fabrics may alter the recommended transfer size, affecting adhesion. |

| Testing | Experimenting with sizes on sample pieces is essential before large orders. |

Summary

DTF Transfers are integral to the quality of printed designs, making it crucial to understand the role of size in this process. The dimensions of your transfers not only affect their visibility but also their durability, ensuring they can withstand wear. By adhering to appropriate size guidelines and leveraging modern tools and technologies, decorators can significantly improve their results. Through careful planning and consideration of factors such as fabric type and design complexity, businesses can enhance their DTF transfers and ensure customer satisfaction. In conclusion, prioritizing the right sizes in DTF printing is essential for achieving high-quality outputs and fostering client trust.