DTF transfers are revolutionizing the world of custom apparel printing, providing a seamless and vibrant solution for applying intricate designs to fabrics. As the popularity of Direct-to-Film (DTF) transfers continues to rise, understanding the various DTF transfer sizes becomes essential for achieving impeccable results. From striking logos on T-shirts to bold graphics on sweatshirts, DTF transfers can cater to a multitude of design needs with precision and flair. With proper DTF transfer techniques, you can ensure that each application not only showcases vibrant colors but also maintains clarity across different fabric types. In this guide, we’ll explore how to choose the best DTF transfers for your projects, optimizing your designs for impeccable application every time.

In the ever-evolving landscape of custom apparel, Direct-to-Film (DTF) printing methods are gaining traction as a preferred choice among designers and businesses alike. This innovative technique leverages unique transfer films to apply stunning graphics onto a wide range of garments, from t-shirts to athletic wear. The beauty of DTF printing lies in its ability to enhance fabric with rich colors and fine details, accommodating a variety of design dimensions. By exploring options such as DTF transfer sizes and printing methods, you can elevate the quality of your apparel projects and stand out in a competitive market. Whether you need small logos or large, eye-catching designs, understanding the nuances of DTF transfer applications can dramatically improve your overall output.

Exploring the Benefits of DTF Transfers for Custom Apparel

**DTF transfers** have revolutionized the world of custom apparel printing by offering unparalleled versatility and quality. One of the significant advantages of DTF transfers is their ability to produce vibrant colors that pop on any fabric. This is particularly beneficial for designers aiming to create eye-catching graphics that leave a lasting impression. Additionally, DTF transfers allow for intricate details and designs that traditional methods struggle to reproduce, making them ideal for small logos and text placement.

Another benefit of DTF transfers is their adaptability across different types of garments. Whether you’re working with cotton, polyester, or blends, these transfers adhere well without compromising the fabric’s integrity. This means you can confidently create designs for a wide array of custom apparel, from sleek T-shirts to cozy hoodies. Moreover, DTF transfer techniques have seen advancements in technology that ensure durability, allowing the print to withstand wear and repeated washing without fading.

Understanding DTF Transfer Sizes: A Guide for Designers

When it comes to **DTF transfer sizes**, getting it right is crucial to achieving professional results. Each project may require different dimensions to maintain clarity and visual impact. For instance, small transfers are typically suitable for discreet branding on the left breast area of shirts or caps. In contrast, medium transfers provide a perfect balance for T-shirts, ensuring that the design remains prominent yet stylish without overwhelming the overall look.

For larger designs, such as those intended for hoodies or full-front prints on T-shirts, opting for large transfers ensures that the artwork is visually striking. However, it’s essential to match the transfer size with the appropriate garment dimensions to avoid distortion during application. Understanding how to choose the right size for your DTF transfers will significantly enhance the quality of your custom apparel designs and ultimately lead to greater customer satisfaction.

The Art of Choosing the Best DTF Transfers

Selecting the **best DTF transfers** can significantly impact the outcome of your projects. It’s not just about the design; the quality and suitability of the transfer for the intended fabric are paramount. High-quality DTF transfers are designed to provide excellent adhesion and durability, ensuring that the finished product looks great and lasts long. Always consider the texture and weight of the fabric you will be printing on, as these factors influence how the transfer interacts with the material.

It’s also essential to look into reputable suppliers when shopping for DTF transfers. Top brands like Heat Transfer Warehouse and Supercolor offer a variety of options tailored to specific printing techniques, fabric types, and user needs. By investing time in choosing the best-quality transfers, you can streamline your production process and ensure that your custom apparel not only meets but exceeds customer expectations.

DTF Transfer Techniques for Crisp and Vibrant Designs

Employing the right **DTF transfer techniques** is crucial for achieving crisp, vibrant designs. One of the critical aspects of the DTF process is the choice of ink. Utilizing high-quality inks, such as water-based or plastisol inks, can enhance color vibrancy and adhesion on various fabrics. Moreover, the printing process itself involves detailed techniques that ensure designs maintain their integrity during application, leading to stunning end products.

In addition to ink quality, proper temperature and pressure settings during the heat press application are essential for the transfer’s success. By following manufacturer guidelines for temperature and pressing times, you can significantly reduce issues such as peeling or fading. Familiarizing yourself with these techniques allows you to maximize the impact of your DTF transfers, creating beautiful custom apparel that stands out in the marketplace.

Trends in DTF Transfers: What’s New in 2023?

As of 2023, the world of **DTF transfers** is constantly evolving, with new trends emerging that enhance the printing experience. One notable trend is the introduction of customizable transfer sizes and templates that cater to specific fabric types or artist requirements. This flexibility allows users to tailor their printing solutions to align perfectly with their unique production needs, leading to a more streamlined workflow.

Furthermore, advancements in film technology have also emerged, providing options that enhance adhesion and color vibrancy. As manufacturers innovate, they are offering products that allow for even more robust and resilient prints. Staying informed about these trends ensures that designers and printers can leverage the latest tools and techniques, pushing the boundaries of creativity in custom apparel printing.

Application Tips for Achieving Perfect DTF Transfers

Applying **DTF transfers** correctly is crucial for achieving the desired results. For successful application, it is vital to adhere to specific guidelines regarding heat settings and pressing time. Generally, DTF transfers work best at temperatures between 325°F and 375°F, and the pressing time should be adjusted based on the transfer size and fabric type. These details may seem minor, but they have a significant impact on the quality of the final product.

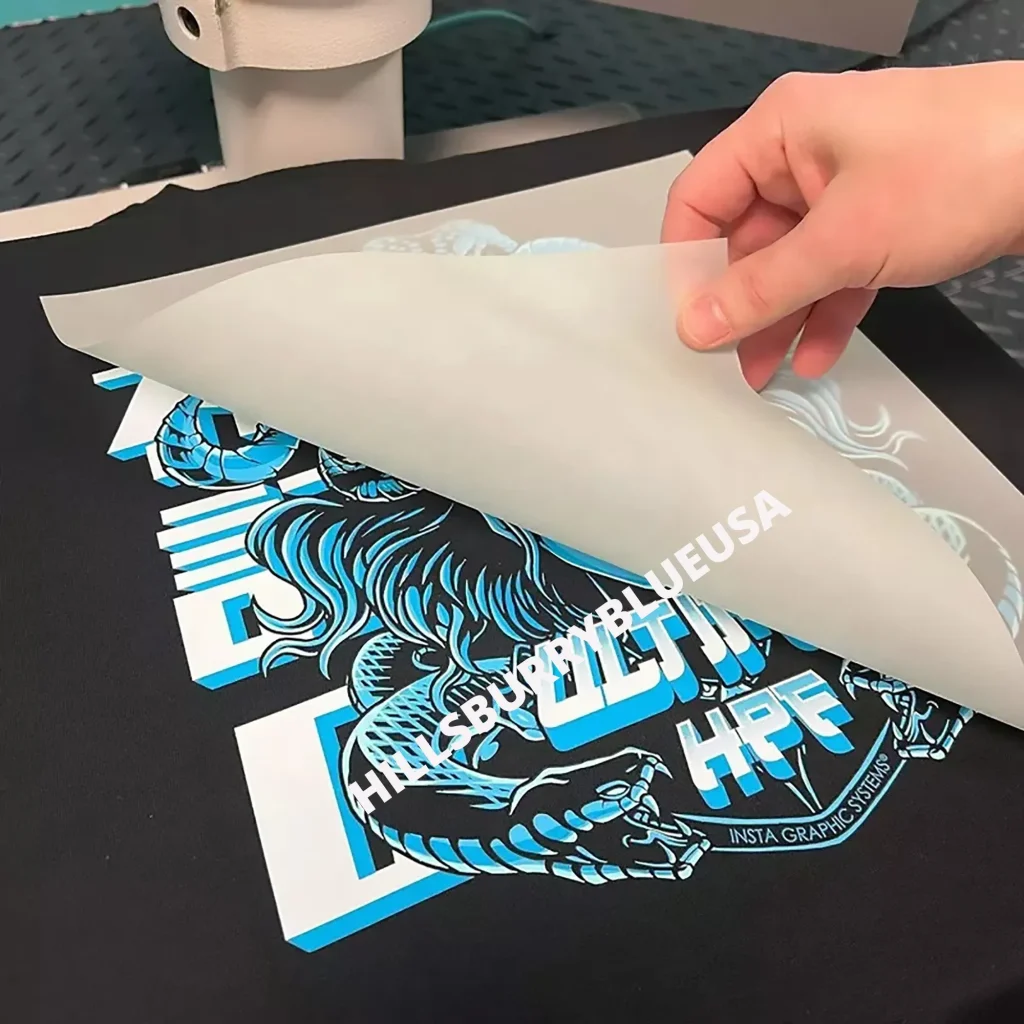

In addition, proper cooling techniques after pressing play a critical role in ensuring that transfers adhere correctly. Allowing the transfer to cool before peeling yields the best results, helping to maintain the integrity of the design. By following these simple yet effective application tips, you can enhance the durability and appearance of your DTF transfers, ensuring long-lasting satisfaction for your custom apparel projects.

Frequently Asked Questions

What are the best DTF transfers for vibrant custom apparel designs?

The best DTF transfers for vibrant custom apparel designs are those made with high-quality films and inks. Look for suppliers that offer detailed color profiles and samples. Using vibrant DTF transfers can ensure your designs pop and maintain their integrity after laundering.

How do DTF transfer sizes impact the final look of custom apparel printing?

DTF transfer sizes significantly affect the final look of custom apparel printing by determining the visibility and clarity of the design. Small DTF transfers work best for logos and subtle details, while medium and large sizes create bold, eye-catching graphics that enhance larger apparel spaces.

What DTF transfer techniques ensure optimal adhesion to fabric?

To ensure optimal adhesion of DTF transfers to fabric, use a heat press set between 325°F and 375°F for the recommended pressing time of 10-15 seconds. Additionally, selecting the right DTF transfer size and quality materials can further enhance adhesion and durability.

Can I use DTF transfers on different fabric types?

Yes, DTF transfers are versatile and can be applied to various fabric types, including cotton, polyester, and blends. However, ensure you are selecting the correct transfer size according to the fabric to maintain the quality and appearance of your custom apparel.

What is the range of DTF transfer sizes available for custom projects?

DTF transfer sizes typically range from small (2-4 inches) for logos to medium (8-12 inches) for standard graphics, and large (12 inches or more) for full-front designs. This range allows for diverse applications across different custom apparel projects.

How do I choose the best DTF transfer for my project?

Choosing the best DTF transfer for your project involves considering the design complexity, desired visibility, and the fabric type. Look for high-quality transfers that align with your specific size requirements to achieve the best results in your custom apparel printing.

| Size Category | Description | Ideal Use Cases |

|---|---|---|

| Small Transfers | Typically used for logos and intricate designs, usually measuring 2-4 inches wide. | Left breast area of shirts, sleeves, or for branding purposes. |

| Medium Transfers | Strikes a balance between visibility and subtlety, usually around 8-12 inches wide. | Standard graphic designs on T-shirts or tote bags, personalizing items. |

| Large Transfers | Perfect for full-front prints and typically more than 12 inches in width. | Full-front prints on T-shirts and back prints on hoodies. |

Summary

DTF transfers are crucial for achieving stunning results in custom apparel projects, as they allow for precise and adaptable design application across various fabric types. By selecting the appropriate size for your DTF transfers, whether small, medium, or large, you enhance the visual appeal and ensure that your designs maintain clarity and permanence. Staying updated with manufacturers’ offerings and guidelines will provide you with the knowledge needed to make informed decisions, enabling your apparel creations to truly stand out. Emphasizing quality film, inks, and precise application techniques further guarantees the longevity and vibrancy of your transferred designs, making DTF transfers an effective choice for both hobbyists and professionals in the garment industry.