If you’re eager to elevate your fabric design game, DTF Transfer stands out as the modern printing technique that can transform your creative visions into reality. This innovative method, known as Direct-to-Film printing, expertly combines vibrant colors and intricate details on a variety of fabrics. Whether you’re crafting custom apparel or exploring print on demand options, DTF transfer offers flexibility that traditional methods like heat transfer printing simply cannot match. With DTF, you have the ability to design and produce stunning prints that are both durable and visually captivating. Join the revolution of custom apparel printing and discover how DTF transfer can enhance your artistic expression!

Exploring new frontiers in textile decoration, Direct-to-Film printing, also referred to as DTF technology, represents a leap forward in the world of fabric customization. This process allows artists and creators to seamlessly infuse their designs onto materials, enabling unique expressions in fabric design that were once limited by traditional printing methods. The heat transfer technique involved in this innovative approach ensures that every intricate detail and vibrant hue is accurately preserved on a range of textiles, making it a preferred choice for those looking to engage in custom garment creation. As the demand for personalized prints continues to rise, understanding DTF principles opens the door to endless possibilities in the realm of print on demand and custom apparel.

Understanding the Fundamentals of DTF Transfer

DTF Transfer, or Direct-to-Film transfer, is revolutionizing the way we view custom apparel printing. Unlike conventional printing methods, DTF utilizes a specialized film and water-based inks, which allows for detailed and vibrant imagery. This process elevates the quality of prints by enabling compatibility with diverse fabric types such as cotton and polyester. As designers explore DTF, they find that its versatility offers the opportunity to print intricate designs that were previously challenging to achieve with methods like heat transfer printing.

Furthermore, DTF Transfer is not just about aesthetics; it emphasizes durability as well. The prints are meant to withstand multiple washes without fading, thanks to the strong bond created during the heat transfer process. This reliability makes it an ideal choice for both promotional products and everyday wear, catering to the needs of burgeoning small businesses and craft enthusiasts alike.

The Step-by-Step DTF Transfer Process

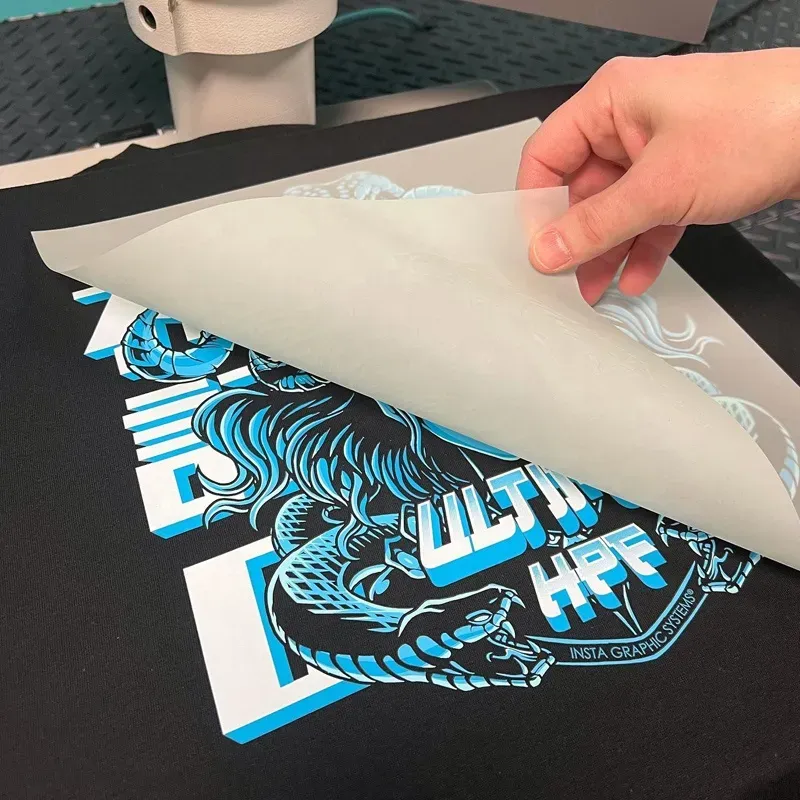

Creating your stunning designs using DTF transfer involves a clear, methodical approach. Initially, you’ll need graphic design software to create your artwork, ensuring that your designs are both unique and tailored to the strengths of the DTF printing process. Once completed, the design is printed onto a special release film, which acts as the medium through which the design will be transferred onto your chosen fabric. Each step in this process is critical; the precision in design and printing can significantly influence the quality of the final product.

Upon finishing the print on the film, an adhesive powder must be applied evenly to the design. This powder is a vital component in ensuring that your print successfully adheres to the fabric during the heat application phase. The heat press should be set to the right temperature and pressure, generally around 305°F for about 15-20 seconds, allowing the adhesive to activate and bond with the fabric correctly. Following this, the cooling and peeling process must be executed attentively to guarantee a flawless result.

Exploring the Benefits of DTF Printing

One of the most significant advantages of DTF printing is its unparalleled versatility in fabric options. Designers are no longer confined to specific materials; DTF can be effectively used on a wide range of fabrics including cotton, polyester blends, and more. This flexibility opens doors for creative possibilities, allowing artists to explore new dimensions in fabric design without limitations.

Additionally, the eco-friendly nature of DTF printing is becoming increasingly relevant in today’s environmentally conscious market. Many DTF inks are water-based, which minimizes the ecological impact, contrasting sharply with traditional solvent-based inks that often harm the environment. This sustainable attribute appeals to both businesses and crafters looking to reduce their footprint while still producing stunning, high-quality designs.

Current Trends Shaping DTF Transfer

The momentum behind DTF transfer is gaining traction, particularly among small business owners and creative crafters. As more users explore DTF techniques, communities and platforms dedicated to sharing insights and best practices continue to emerge. This shift is fostering an environment where resources such as workshops, tutorials, and online courses are readily available to assist newcomers in mastering DTF printing.

Anticipation for future trends is high, with expectations for increased innovations in DTF technologies. As the market grows, innovations will continue to enhance the efficiency and accessibility of DTF transfer processes. Engaging with these trends not only empowers practitioners to elevate their craft but also positions them at the forefront of an industry marked by rapid advancements.

The rise in demand for DTF printing is indicative of its impact on the custom apparel industry, where personalization and quality are prized. Many crafters are diversifying within the niche by implementing DTF alongside other methods like print on demand, allowing for more comprehensive offerings in their product lines.

Design Tips for Successful DTF Printing

When embarking on your DTF printing journey, design plays a pivotal role. Utilize vibrant colors and intricate details to make your creations stand out. It’s important to understand the capabilities and limits of DTF printing; detailed designs often yield the best results. Using high-resolution files ensures that clarity is maintained throughout the printing process, which is crucial for producing appealing custom apparel that attracts customers.

Additionally, experimenting with layering colors and textures can greatly enhance the visual appeal of your designs. DTF allows for mixing colors seamlessly, and taking advantage of this can lead to unique and powerhouse layouts. Remember to consider the fabric’s color and texture when creating your design, as these elements can significantly influence the final look of your print on different materials.

Conclusion: Embracing DTF Transfer for Future Designs

As we conclude our exploration of DTF transfer, it’s clear that this method provides an excellent avenue for creativity and entrepreneurship. The vibrant and durable prints created through DTF technology resonate well with consumers, paving the way for exciting possibilities in custom apparel printing. Whether you’re a hobbyist looking to craft compelling pieces or a business owner aiming to expand your product offerings, DTF printing presents a golden opportunity to realize your vision.

The flexibility, eco-friendliness, and potential for intricate designs that DTF printing encapsulates make it the future of fabric design. With an array of resources available to support newcomers, there’s never been a better time to dive into the world of DTF transfer. Gather your materials and unleash your creativity; the world of custom apparel awaits!

Frequently Asked Questions

What is DTF Transfer and how does it work?

DTF Transfer, or Direct-to-Film transfer, is a modern printing technique that applies detailed and vibrant designs to various fabrics, including cotton and polyester. The process begins with printing your design on a special film, applying a powder adhesive, and then using heat transfer to bond the design to the fabric. This method is becoming increasingly popular for custom apparel printing due to its versatility and high-quality results.

What are the benefits of using DTF printing for custom apparel?

DTF printing offers numerous benefits for custom apparel, including versatility in fabric options, eco-friendly water-based inks that reduce environmental impact, and lower setup costs ideal for small businesses. The ability to print intricate designs on a wide range of textiles makes DTF transfer a frontrunner for fabric design and custom apparel projects.

Can I use DTF Transfer on different types of fabrics?

Yes, DTF Transfer is highly versatile and works effectively on a wide variety of fabric types. It can be applied to cotton, polyester, and blended fabrics, making it suitable for countless applications, from promotional products to custom apparel printing.

How do I ensure high-quality results with DTF printing?

To achieve high-quality results with DTF printing, it is crucial to use a specialized DTF printer for optimal color accuracy and resolution. Ensure your design is detailed and vibrant, apply adhesive evenly over the printed film, and use the correct heat and pressure settings during the heat transfer process. Following these steps will greatly improve the sustainability and durability of your fabric designs.

Is DTF transfer eco-friendly compared to other printing methods?

Yes, DTF transfer is considered more eco-friendly than traditional printing methods due to the use of water-based inks instead of solvent-based options. This reduces the environmental impact significantly, allowing you to create stunning designs without compromising on sustainability, making it a favorable choice for conscientious designers.

What tools do I need to get started with DTF Transfer printing?

To start with DTF Transfer printing, you will need a DTF printer, special release film for printing your designs, powder adhesive, a heat press for applying your designs to fabric, and graphic design software such as Adobe Illustrator or CorelDRAW for creating your artworks. Having these tools will enable you to efficiently produce high-quality custom apparel and fabric designs.

| Key Points | Description |

|---|---|

| What is DTF Transfer? | DTF Transfer is an innovative printing technique that applies detailed designs to textiles, allowing for versatility across different fabrics like cotton and polyester. |

| Step-by-Step Guide | The DTF process includes various steps starting from understanding the process, creating a design, printing on film, applying adhesive, heat transfer, and finishing by peeling. |

| Benefits of DTF Transfer | DTF offers versatile fabric options, eco-friendly printing with water-based inks, and low setup costs, making it suitable for small businesses. |

| Current Trends | DTF printing is increasingly popular among small businesses and home crafters, with many resources available for learning and improving skills. |

Summary

DTF Transfer is a revolutionary method for creating vibrant and detailed designs on textiles, making it an essential technique for both novice and experienced designers alike. With its multi-step process that ensures the quality and durability of prints, DTF Transfer allows for customization on a variety of fabric types. The advantages range from eco-friendliness to low startup costs, making it accessible for many. As the demand for this innovative technique grows, resources and communities are emerging to support enthusiasts in honing their skills. Embrace DTF Transfer today and unlock the potential of stunning textile designs that truly stand out.