In the dynamic realm of custom apparel printing, the DTF Gangsheet Builder has emerged as a game-changing innovation, propelling businesses toward more efficient production methods. This advanced printing solution facilitates the simultaneous application of multiple designs onto a single sheet, maximizing output while minimizing waste. Unlike traditional printing techniques that can be limiting, DTF printing offers unmatched versatility and high-quality results, making it an appealing choice for many companies. As the demand for personalized garments surges, understanding the benefits of DTF compared to conventional options, such as screen printing, is essential. This guide will explore the various aspects that set the DTF Gangsheet Builder apart and help you navigate your printing options in today’s competitive market.

When delving into the landscape of garment decoration, the Direct-To-Film (DTF) Gangsheet Builder represents a revolutionary shift from time-honored methods such as screen printing and direct-to-garment (DTG) options. This modern approach to gangsheet printing stands out for its ability to generate intricate designs efficiently, catering to the growing need for customization in the apparel industry. By harnessing DTF printing technology, businesses can streamline their processes, achieve vibrant colors, and maintain high detail on a variety of fabrics. As traditional printing methods face limitations in versatility and cost, exploring alternatives like DTF can provide noteworthy advantages for those seeking to enhance their custom apparel offerings.

Understanding DTF Gangsheet Builder in Depth

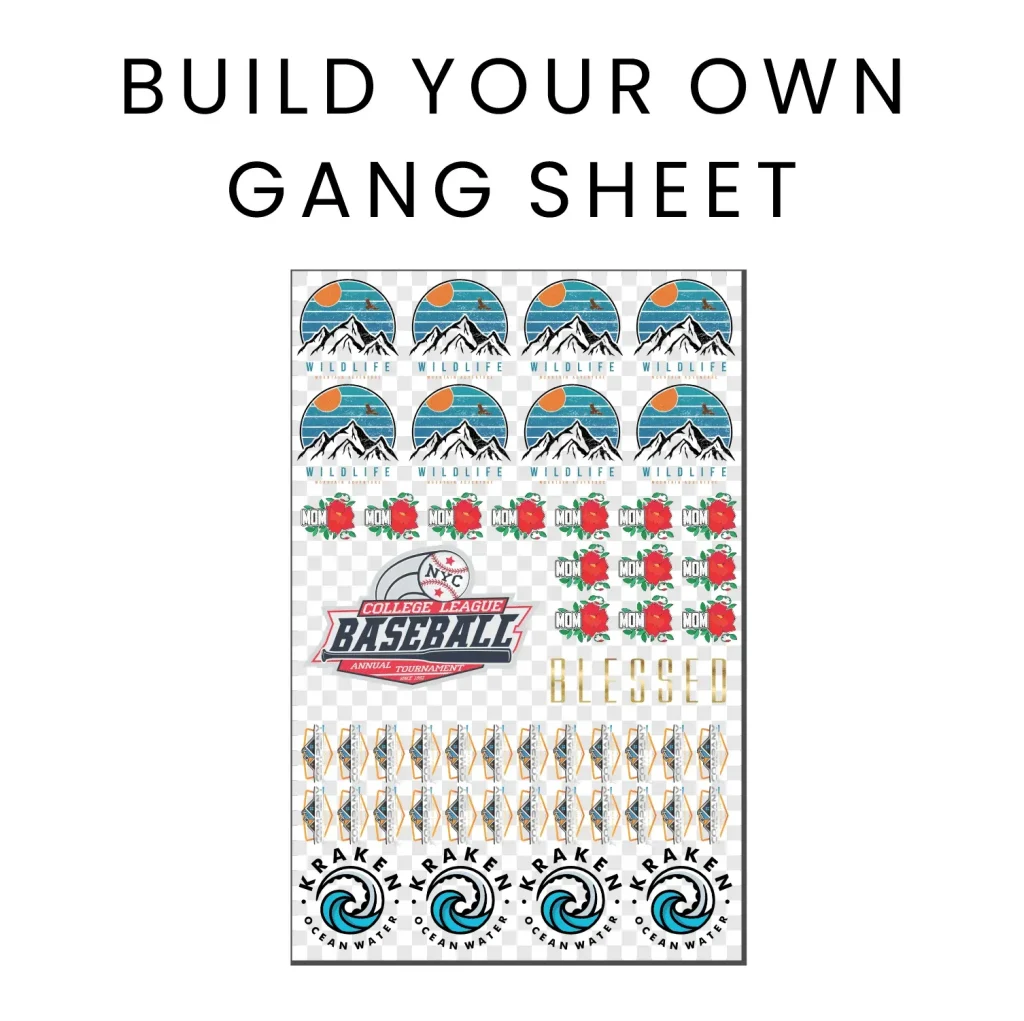

The DTF Gangsheet Builder is a revolutionary tool that optimizes the process of creating custom designs for apparel. By allowing multiple designs to be printed simultaneously on a single sheet, it offers businesses significant efficiencies in both time and cost. This method stands out, especially for small to medium-sized orders, as it reduces material waste and speeds up production times compared to traditional screen printing methods.

Moreover, the flexibility of the DTF Gangsheet Builder extends beyond just efficiency; it also caters to a diverse range of fabrics. Whether printing on cotton, polyester, or blends, this technique ensures vibrant colors and high-quality details, making it a preferred choice among custom apparel providers. As the demand for personalized clothing continues to rise, the Gangsheet Builder’s contribution to the DTF printing landscape is becoming increasingly significant.

Advantages of DTF Printing Over Traditional Methods

DTF printing provides several advantages that make it appealing compared to traditional methods like screen printing and DTG printing. One key benefit is its ability to produce high-detail designs characterized by rich colors and excellent durability. Unlike traditional screen printing, where setup costs can be prohibitive for smaller runs, DTF printing allows custom designs to be made without extensive preparation, thereby making it economical and efficient for lower quantities.

Additionally, DTF’s compatibility with various fabric types ensures that businesses can cater to a wider audience. While traditional methods have their respective strengths, particularly in bulk orders, they often struggle with the intricate designs and color variations that DTF excels in. This adaptability allows companies to maintain a competitive edge in the fast-paced world of custom apparel.

Cost Analysis: DTF Printing versus Traditional Techniques

When examining the cost efficiency of DTF printing compared to traditional printing methods, several factors come into play. The initial investment in DTF equipment, including printers and heat presses, might be substantial. However, the per-unit pricing drastically decreases as production scales up, particularly because multiple designs can be printed on a gang sheet. This feature significantly reduces the overall cost per unit, making DTF a financially viable option for businesses.

In contrast, traditional screen printing often entails higher upfront costs due to setup fees, which can be a barrier for smaller orders. Although these costs can be amortized over large runs, it’s important to note that DTF’s lower waste generation and quicker turnaround times lend it an advantage in cost-effectiveness, especially for custom apparel printing where design freedom is paramount.

Quality Comparison: DTF Prints vs. Traditional Screen Prints

The quality of prints is a critical factor for businesses in the custom apparel industry. DTF printing is known for its high-resolution outputs, resulting in vibrant and detailed prints that maintain integrity over time. Unlike traditional methods, where intricate designs may lose detail, DTF excels in preserving fine graphics, making it an excellent choice for complex artwork.

On the other hand, while traditional screen printing is tried and tested, it may have limitations regarding color depth and gradient transitions. Screen printing often performs better with solid colors, but for businesses aiming to create detailed graphics or photographic images, DTF offers a superior alternative in terms of detail and visual impact. This makes understanding the quality differences crucial for makers and businesses aiming to satisfy diverse customer needs.

Environmental Considerations in Printing Methods

Sustainability is increasingly becoming a concern in the apparel industry, and the environmental impacts of printing methods are under scrutiny. DTF printing technology is favorable as it generally uses less water and produces less waste compared to traditional techniques. As this method utilizes specially formulated inks and film, the overall chemical usage is also lower, aligning with the growing demand for eco-friendly practices in manufacturing.

Conversely, traditional printing methods like screen printing often involve more substantial resource consumption and waste generation. While there are movements towards more sustainable practices within the screen printing community, DTF remains ahead due to its inherent design efficiencies and minimal environmental footprint. This shift towards sustainability is critical, as consumers increasingly choose brands that prioritize eco-friendly production.

The Future of DTF Printing in Custom Apparel

Looking forward, the DTF printing technology continues to evolve, bringing about innovations that are reshaping the custom apparel landscape. Enhanced printer models are emerging, offering faster printing speeds and improved quality, which are becoming essential as businesses ramp up their production capabilities. This technological advancement is crucial, especially for businesses that handle high volumes of custom orders.

The rising trend of customization in apparel is also propelling DTF printing into the spotlight. Unlike traditional methods that may struggle with quick turnovers, DTF allows for rapid production of personalized or limited-edition designs. As a result, businesses that leverage DTF technology are likely to achieve a competitive advantage, catering swiftly to customer demands and tapping into the growing market for unique apparel.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance custom apparel printing?

The DTF Gangsheet Builder is a tool designed for Direct-To-Film (DTF) printing that allows multiple designs to be printed on a single sheet. This method maximizes efficiency and reduces waste, making it an ideal choice for businesses in custom apparel printing.

How does DTF printing compare to traditional screen printing in terms of quality?

DTF printing is known for its vibrant colors and ability to maintain fine details, often outperforming traditional screen printing, especially for intricate designs. While screen printing excels in bulk and solid colors, DTF provides higher quality for complex graphics.

What are the cost benefits of using the DTF Gangsheet Builder over traditional printing methods?

Using the DTF Gangsheet Builder can be more cost-effective, particularly for smaller runs. By printing multiple designs on one sheet, businesses reduce material waste and lower the cost per unit, making it more efficient than traditional screen printing setups.

Can the DTF Gangsheet Builder be used on a variety of fabrics?

Yes, the DTF Gangsheet Builder is versatile and can be used on various fabrics such as cotton, polyester, and blends, making it an effective choice for a wide range of custom apparel printing applications.

What environmental advantages does DTF printing have over traditional printing techniques?

DTF printing generally has a lower environmental impact compared to traditional printing methods, as it reduces chemical usage and water consumption. Innovations in DTF technology continue to enhance its eco-friendliness compared to traditional dyeing processes.

Is the DTF Gangsheet Builder a suitable option for high-volume custom apparel orders?

While the DTF Gangsheet Builder is ideal for small to medium runs due to its cost and efficiency, it can also manage high-volume orders effectively by maximizing production speed and minimizing waste, making it a competitive choice against traditional printing methods.

| Aspect | DTF Gangsheet Builder | Traditional Printing |

|---|---|---|

| Technology | Innovative printing via heat transfer; multiple designs on one sheet. | Includes methods like screen printing and DTG; well-established. |

| Advantages | High detail, vibrant colors, variety of fabrics, cost-effective for small runs. | Durability in bulk orders, excellent color accuracy, proven techniques. |

| Cost Efficiency | Reduced waste; lower costs with scaling. | Higher setup costs for small runs, but efficient in bulk orders. |

| Quality | Excels in fine details and vibrant designs. | Strong durability, but may lack in replicating intricate designs. |

| Environmental Impact | Less chemical and water usage; evolving with tech advancements. | Higher resource consumption but gradually becoming greener. |

Summary

The DTF Gangsheet Builder is revolutionizing the custom apparel printing industry by combining efficiency, cost-effectiveness, and quality. This innovative method allows businesses to produce high-detail prints with vibrant colors while minimizing waste and maximizing production capabilities. As the demand for personalized apparel continues to rise, the DTF Gangsheet Builder emerges as a flexible solution that caters to modern printing needs, significantly enhancing productivity and satisfaction among customers. Embracing this technology not only facilitates a smooth operation for apparel businesses but solidifies their position in a competitive market.