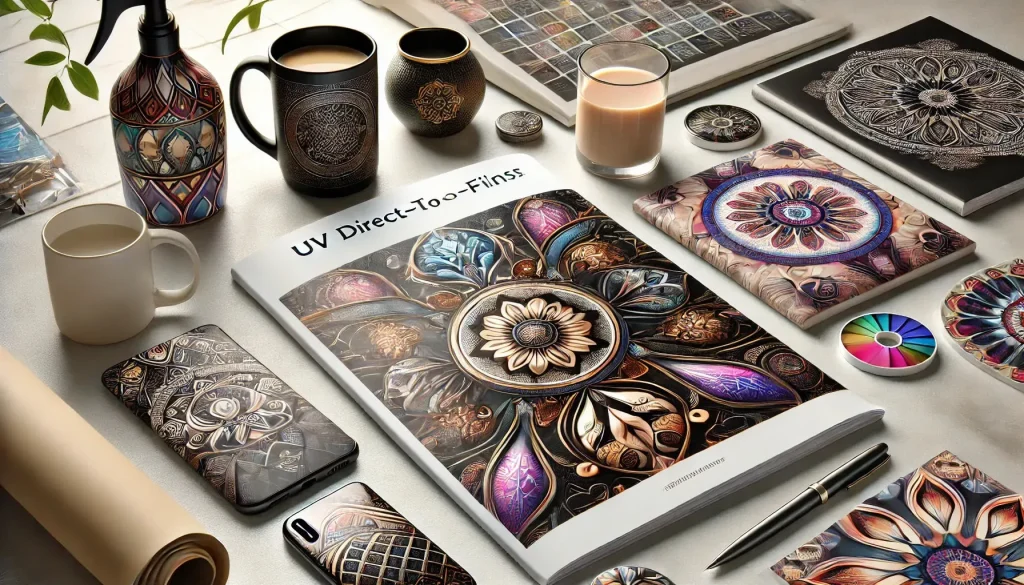

In the dynamic world of printing, **UV DTF Transfer Techniques** stand out as a revolutionary approach that merges innovation with creativity. This method allows artists and designers to produce vibrant, high-resolution prints on a variety of substrates, fundamentally transforming the crafting landscape. By utilizing advanced UV curing technology, UV DTF empowers users to explore their artistic visions in ways that traditional methods simply cannot achieve. Whether printing on textiles, metals, or ceramics, the versatility of this technique opens up a plethora of applications, including custom apparel and bespoke home decor. As the demand for sustainable printing solutions increases, UV DTF techniques emerge as a frontrunner, combining high quality with environmentally friendly practices, making them an appealing choice for modern creators.

UV DTF transfer, or direct-to-film transfer, represents a blend of cutting-edge technology and artistic expression, appealing to a diverse audience of makers and designers. This pioneering printing technique leverages ultraviolet curing, enabling prints to dry quickly while maintaining exceptional vibrancy and detail. Artists are increasingly discovering the wide-ranging applications of this method, from crafting unique merchandise to developing personalized gifts and home decor items. With a focus on sustainable practices, UV DTF allows creators to engage in eco-conscious printing without sacrificing quality, positioning it as a preferred choice in current creative markets. As new applications for this innovative approach emerge, the possibilities for creative expression continue to expand.

Understanding the Basics of UV DTF Transfer

UV DTF (Direct-to-Film) transfer is a cutting-edge printing method that leverages the power of ultraviolet (UV) light to cure inks, resulting in vibrant and durable designs. This technique operates by printing an image directly onto a special film using UV inks, which are then cured with UV light to ensure quick setting. As the ink dries rapidly, it solidifies to form high-resolution images that adhere to a wide variety of materials, supporting creativity in multiple applications.

This innovative approach transcends the limitations of traditional printing methods, making it possible to achieve intricate details and a rich color palette. Creators and manufacturers appreciate UV DTF transfer for its versatility, as it can be applied to substrates ranging from soft textiles to rigid materials like metal and glass. This adaptability enables artists to explore new creative avenues, enhancing their project potential.

The Advantages of UV DTF Over Conventional Printing

One of the standout benefits of UV DTF transfer techniques is their efficiency compared to conventional printing methods. Unlike traditional silkscreen or transfer methods that may require multiple steps and lengthy drying times, UV DTF simplifies the process. The instant curing of UV inks not only speeds up production times significantly but also reduces the risk of smudging or mistakes during handling.

Moreover, UV DTF printing offers superior print quality with its ability to produce sharp images and vibrant colors. The incorporation of various finishes, including matte and glossy, allows for customizations that can elevate any design. This flexibility provides creators with the opportunity to cater to the specifics of their projects, satisfying aesthetic demands while ensuring durability, which is essential for applications in custom merchandise and promotional items.

Exploring UV DTF Applications Across Industries

The versatility of UV DTF transfer has opened doors across multiple industries, transforming the way designers approach projects. From fashion to interior decor, UV DTF is enabling the creation of unique products that resonate with individual tastes. The ability to print directly on diverse materials means fashion designers can produce custom apparel that stands out, while art creators can craft personalized home decor pieces that reflect their artistic vision.

In the promotional sector, businesses are recognizing the benefit of utilizing UV DTF transfers for branded merchandise. This method allows for highly customizable items such as drinkware, signage, and gifts, fostering brand loyalty and visibility. The possibilities seem endless, as creators continue to experiment and push the boundaries of their products through inventive UV DTF applications.

Sustainability and UV DTF Printing Practices

As the world moves toward more environmentally friendly practices, UV DTF transfer techniques are adapting to meet the demands of sustainable printing. Manufacturers are prioritizing eco-friendly inks that minimize environmental impact while maintaining print quality. This shift allows companies to appeal to a growing demographic of conscious consumers who value sustainability, making UV DTF not just a smart manufacturing choice but also a responsible one.

Implementing sustainable practices in UV DTF production, such as using recyclable materials and energy-efficient processes, further supports a brand’s commitment to reducing its carbon footprint. By adopting these methods, businesses can enhance their marketability and align with consumer preferences, ultimately contributing to a more eco-conscious printing landscape.

Enhancing Your Skills with UV DTF Workshops and Education

Continuous learning is crucial for anyone looking to master UV DTF transfer techniques. A plethora of workshops, online tutorials, and dedicated courses are available for creators at all levels, providing hands-on experience and insights into the latest developments in the field. Engaging in these educational resources can significantly bolster your understanding of the technology, enabling you to stay ahead of trends and innovations.

Community-based learning is also an effective way to enhance your skills. Joining local maker spaces or participating in creative forums allows you to exchange ideas and techniques with fellow artists. Collaborating and sharing your work not only inspires creativity but also fosters a supportive environment for growth, ultimately leading to enhanced proficiency in UV DTF techniques.

The Future of UV DTF Technology and Market Growth

The growth trajectory of the UV DTF market indicates a promising future for this innovative printing method. With increasing demand for customization in various industries, the adoption of UV DTF transfer techniques is set to rise significantly. As creators become more aware of the benefits offered by UV DTF, including its versatility and high-quality output, it is expected that investment in related equipment and supplies will flourish.

Looking forward, advancements in UV DTF technology will likely continue to enhance capabilities and efficiency, opening even more opportunities for creative expression. As manufacturers strive for improved ink formulations and curing systems, the landscape of custom printing will evolve, leading to an exciting era for designers, businesses, and consumers alike.

Frequently Asked Questions

What is UV DTF transfer and how does it work?

**UV DTF transfer** is a modern printing technique that utilizes UV inks printed onto a special film. After printing, the film is cured with UV light, rapidly drying the ink. This cured film can then be transferred onto various substrates like textiles, wood, metal, and ceramics, producing vibrant, long-lasting designs suitable for custom apparel and décor.

What are the advantages of using UV DTF transfer techniques in creative projects?

The **advantages of UV DTF transfer techniques** include the ability to print on a wide range of materials, high-quality vibrant colors, and quick drying times due to UV curing. This versatility allows artists to experiment creatively and produce intricate designs that stand out in the competitive crafting and printing markets.

How can I achieve sustainability in UV DTF applications?

To achieve sustainability in **UV DTF applications**, opt for eco-friendly inks and materials. Many manufacturers are now offering sustainable options that reduce environmental impact. Additionally, employing efficient production techniques and minimizing waste will further enhance your eco-conscious printing practices.

What types of materials are compatible with UV DTF transfer techniques?

**UV DTF transfer techniques** are compatible with an extensive array of materials including textiles, metals, wood, ceramics, and plastics. This compatibility allows artists and designers to explore diverse applications and unleash their creativity across different project types.

How can I learn more about UV DTF transfer techniques?

To learn more about **UV DTF transfer techniques**, consider attending workshops, webinars, and tutorials available online. Engaging with community forums and maker spaces can also provide valuable insights, resources, and support from fellow creators and industry professionals.

What recent innovations are shaping the future of UV DTF printing?

Recent innovations in **UV DTF printing** include advanced curing systems for faster drying, improved ink formulations for better durability, and expanded compatibility with various substrates. These advancements enhance print quality and efficiency, catering to the evolving demands of the creative and commercial printing industries.

| Aspect | Details |

|---|---|

| Definition of UV DTF Transfer | A printing method combining traditional techniques with UV curing for vibrant designs on various substrates. |

| Recent Innovations | Improvements in curing systems and print quality, enabling high-volume production and efficiency. |

| Material Compatibility | Compatible with textiles, metals, wood, and ceramics, expanding creative possibilities. |

| Sustainability Focus | Development of eco-friendly inks and processes to appeal to environmentally-conscious consumers. |

| Educational Resources | Access to workshops, tutorials, and online communities for skill development. |

| Market Growth | Increasing demand for equipment and supplies due to popularity in custom markets. |

| Creative Practices | Experiment with color layering, mix textures, and incorporate mixed media. |

| Community Engagement | Join online forums and local maker spaces for support and inspiration. |

| Continuous Learning | Stay updated with trends through workshops and trade shows. |

Summary

UV DTF transfer techniques represent a groundbreaking approach to creative expression in the crafting and printing industries. By harnessing the power of innovative technology, versatile material compatibility, and sustainable practices, artists and designers can unlock new frontiers in their work. This method encourages a rich interplay of colors, textures, and mediums, allowing for truly unique creations. Embracing continuous learning and community engagement further enhances skills and inspires fresh ideas, ensuring that the creative journey remains dynamic and fulfilling. With UV DTF transfer techniques, the potential for creativity is limitless.