DTF transfer by size plays a crucial role in achieving the best results in custom DTF printing applications. This innovative process utilizes DTF printing technology to transport vibrant designs onto various fabric types, allowing for high-quality, intricate visuals. Understanding how print size impacts the DTF transfer process is essential for businesses looking to maximize efficiency and meet customer demands. The choice of the best DTF printer can significantly influence not only the size of designs that can be printed but also the overall quality of the finished product. In this guide, we will delve into the nuances of DTF transfer by size and its implications for businesses in the apparel industry, helping you navigate this exciting printing technology for superior outcomes.

When discussing DTF transfer by size, it’s essential to explore this technique through alternative terms. Direct-to-Film (DTF) transfer involves specific dimensions of the prints used in the DTF printing process, which significantly affects the output’s quality and usability. Terms like print dimensions and transfer scale are often used interchangeably when referring to how designs are adapted to varied apparel sizes and styles. By analyzing factors such as fabric compatibility, printer functionality, and market trends, businesses can optimize their custom DTF printing efforts for better production efficacy. This comprehensive exploration reveals the importance of understanding print sizes within the context of DTF technology and its applications in the garment industry.

Machine Size and Its Impact on DTF Printing

The choice of machine size is critical when delving into the DTF transfer process. Businesses aiming for larger print runs typically benefit from larger DTF printers, which are engineered to accommodate expansive designs and continuous usage. This capability is particularly valuable for custom DTF printing projects, which often require robust machines that can handle extensive materials and vibrant prints. Moreover, the scalability of larger printers can accommodate seasonal peaks in demand, allowing businesses to produce a high volume of products efficiently.

Conversely, smaller DTF printers serve a unique purpose in the market. They allow for easy maneuverability and are often less expensive than their larger counterparts, making them a suitable option for startups or small businesses focused on niche markets. These printers enable the production of more personalized and smaller-scale items which have been gaining popularity, particularly in the custom apparel sector. By understanding the operational limits and advantages of different machine sizes, businesses can better align their production capabilities with market demand.

Optimizing Print Size for Different Applications

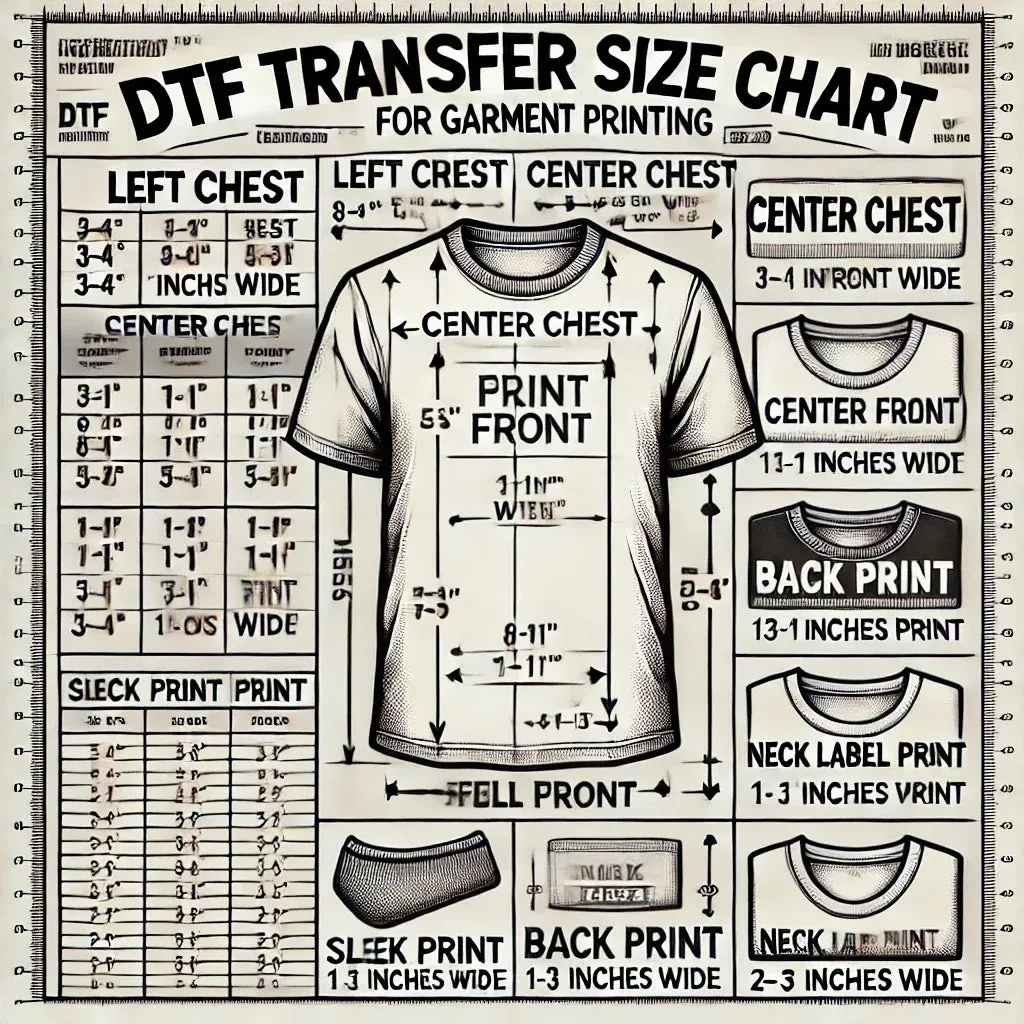

Print size optimization is a multi-faceted consideration in the DTF transfer process. The ideal dimension not only influences the aesthetic appeal of the final product but also its functionality. For example, while T-shirts generally favor designs within a 10×12 inch format to maintain clarity and vibrancy, larger applications like banners might require a more extensive setup. The correlation between print size and application is pivotal in ensuring the quality of the DTF printing technology deployed.

Furthermore, as consumer preferences lean towards personalization and uniqueness, businesses must adapt their designs accordingly. Custom DTF printing enables brands to thrive in a market that values distinctiveness, but doing so effectively requires a nuanced understanding of file preparation and size constraints of the printer. Investigating the compatibility of various artist design sizes with their intended garment types is crucial for maintaining high standards in customer satisfaction.

Choosing the Right Materials for DTF Transfers

Material compatibility plays a significant role in the success of DTF transfers, especially when it comes to size considerations. Different fabrics react uniquely to heat and pressure; hence, the size of prints must be tailored accordingly. For instance, stretchy fabrics necessitate smaller prints to prevent distortion during wear, while more stable materials like cotton can support larger designs without compromising the overall print quality. It’s essential to consider these factors when planning custom DTF printing, as they directly affect durability and performance.

As businesses diversify their offerings and explore new fabric types, achieving mastery in determining the sizes compatible with different materials becomes increasingly important. Using an assortment of fabrics can enhance a brand’s appeal, but understanding the limitations and perfecting print strategies on these various textiles is paramount. By mastering these material interactions, companies can not only improve their production efficiency but also elevate their reputation for quality within the competitive garment printing market.

Maximizing Efficiency in the DTF Transfer Process

Process efficiency remains a cornerstone of successful DTF transfer operations. As printer technology evolves, operational procedures can be optimized not only for faster printing times but also for seamless transitions between different print sizes. Businesses that streamline their workflows and adjust machine settings according to specific design requirements can significantly enhance their productivity, minimizing downtime and facilitating timely project delivery.

Employing automated processes is also a game-changer in achieving efficiency, as it reduces manual handling and error margins. The synergy between a printer’s speed and the print size can dictate the overall output and, consequently, the business’s ability to meet custom order demands. By continuously assessing the relationship between print size, speed, and overall efficiency, businesses can refine their operational practices to align with market needs.

Exploring Latest Market Trends in DTF Technology

The DTF transfer landscape is continually evolving, with emerging trends reshaping how businesses approach printing solutions. As of 2025, there’s a growing emphasis on automation and advanced printing capabilities that enhance production speed without sacrificing quality. Innovations in DTF printing technology also promise improvements in color vibrancy and design detail that appeal to today’s consumers, who increasingly seek visually appealing custom apparel that stands out.

Keeping abreast of market trends is essential for businesses wanting to remain competitive. It involves analyzing shifts toward increased demand for personalization and eco-friendly processes within DTF printing applications. Early adoption of new technology and practices can position a business as a leader in the industry, potentially translating to increased market share and customer loyalty as they adapt their offerings to align with consumer desires.

Balancing Print and Machine Size for Optimal Output

Achieving a harmonious balance between print size and machine size is vital for maximizing output in DTF printing. A larger print can enhance visibility and aesthetic appeal, but it may require equally capable machinery to ensure precision and quality are maintained throughout the printing process. Striking this balance not only helps in managing production capabilities but also directly impacts the cost-effectiveness of operations, which is crucial for maintaining competitive pricing.

On the other hand, understanding the limitations of smaller machines while optimizing the size of designs to fit within those parameters can lead to profitability in niche markets. As businesses calibrate their printer settings to adapt to varying design sizes and complexities, they will find a pathway to enhance customer satisfaction by producing high-quality, customized prints that resonate with their target audience. Exploring these dynamics is essential for sustaining growth in a rapidly evolving printing industry.

Frequently Asked Questions

What should I consider regarding DTF transfer by size when choosing a printer?

When selecting a printer for DTF transfer by size, consider the printer’s maximum printing size, speed, and capability for handling various fabric types. Larger printers are ideal for bulk production and larger designs, while smaller printers are suitable for startups focusing on custom DTF printing and smaller batches.

How does print size affect the quality of DTF transfers?

Print size plays a critical role in the quality of DTF transfers. Smaller prints are often more manageable on various fabrics, while larger designs require careful adjustment to avoid distortion. Designs should typically be within the 10×12 inch range to ensure optimal clarity and adherence during the DTF transfer process.

What types of fabrics are best suited for large DTF transfers?

Cotton fabrics are typically the best choice for large DTF transfers, as they can support larger designs without sacrificing quality. However, it’s essential to ensure that the specific print size aligns with the fabric’s characteristics to prevent any distortion or damage.

How does machine size impact DTF printing applications?

Machine size significantly influences DTF printing applications by affecting production capacity and design versatility. A larger DTF printer allows for continuous roll printing and bigger designs, making it suitable for commercial use, while smaller machines can efficiently handle custom DTF printing for niche markets.

What trends are emerging in DTF transfer by size for 2025?

Emerging trends in DTF transfer by size for 2025 include advancements in print speed, color vibrancy, and durability. There’s a growing focus on automation to improve efficiency and scalability within the DTF transfer process, making it essential for businesses to stay updated with these innovations.

Can you explain the importance of material compatibility when determining DTF transfer by size?

Material compatibility is crucial when determining DTF transfer by size, as different fabrics respond differently to heat and pressure. Ensuring the print size aligns with the material’s properties, especially for stretchy fabrics, is vital to maintain durability and quality in the final product.

| Aspect | Details |

|---|---|

| Overview of DTF Transfer Technology | DTF transfer allows intricate designs and vibrant colors to be printed on various fabrics via heat and pressure. |

| Machine Size | Larger printers handle more substantial bulk designs but cost more, while smaller ones are ideal for limited print sizes and flexibility. |

| Print Size Considerations | Optimal print sizes depend on fabric types; standard sizes for apparel are within 10×12 inches to maintain quality. |

| Material Compatibility | Different fabrics require adjustments in print sizing to avoid distortion or damage; cotton allows larger prints while stretchy fabrics need smaller designs. |

| Process Efficiency | Efficiency relates to printer speed and design sizes; optimizing workflows enhances productivity and meets deadlines. |

| Market Trends | The DTF market is evolving with improvements in speed and automation, necessitating businesses to adapt to remain competitive. |

Summary

DTF transfer by size plays a critical role in determining the efficiency and quality of printed materials. This comprehensive guide outlines how the size of both the printing machine and the designs themselves directly affect the output. Businesses must balance the capabilities of their equipment with the specific size requirements of their projects to optimize production and enhance customer satisfaction. As the DTF market continues to evolve, staying informed about size-related nuances will be crucial for maintaining a competitive edge.