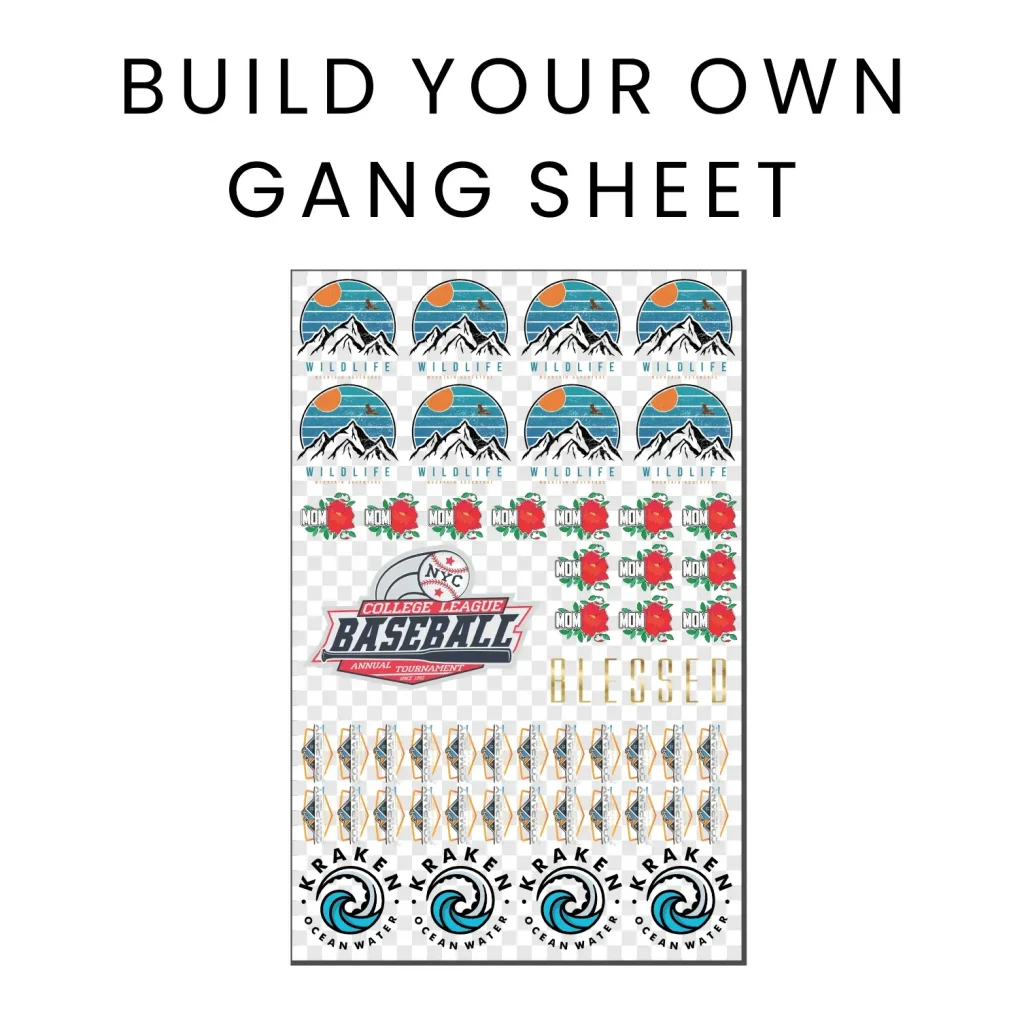

The DTF gangsheet builder stands at the forefront of modern apparel printing, revolutionizing how design and functionality converge in the world of Direct-to-Film (DTF) printing. This innovative tool empowers users to create efficient layouts known as gang sheets, allowing multiple designs to be processed in a single print run. With DTF printing techniques, you can achieve vibrant and durable images on various fabrics, streamlining your workflow and reducing material wastage. As businesses embrace advanced DTF techniques, they discover not only cost-effectiveness but also significant improvements in production timelines. In this guide, we’ll explore the nuances of DTF design preparation to optimize your gang sheet workflow and elevate your printing capabilities to new heights.

The concept of the DTF gangsheet builder is essential for those venturing into the realm of Direct-to-Film printing, offering a strategic method for optimizing print production. Often referenced as layout design software, this tool facilitates the creation of efficient transfer sheets that maximize design output while minimizing waste. By leveraging this approach, users can navigate the complexities of DTF printing for apparel, ensuring that each design is beautifully represented on garments. Additionally, understanding the principles behind gang sheets and how they enhance the DTF process allows businesses to adopt advanced techniques that boost their operational efficiency. Thus, mastering the art of gang sheet building is crucial for anyone looking to excel in the DTF printing landscape.

The Evolution of DTF Printing Techniques

DTF printing has seen a remarkable evolution since its inception, significantly changing how print designers and manufacturers approach garment decoration. Initially celebrated for its vibrant color reproduction and versatility across various textiles, DTF printing has quickly become a favored technique among custom apparel decorators. This evolution has been driven by advancements in ink formulations and printing equipment, which have continuously improved the quality and efficiency of the printing process. By keeping abreast of these advancements, businesses can better cater to market trends and the preferences of their customers.

Moreover, as technology progresses, DTF printing techniques have adopted more environmentally friendly practices. Manufacturers are increasingly focused on creating biodegradable inks and sustainable transfer films that minimize waste and environmental impact. The incorporation of eco-friendly materials into the DTF printing process not only revolutionizes the method but also aligns with the growing consumer demand for sustainability in fashion.

The Role of Gang Sheets in DTF Printing

Gang sheets play a pivotal role in maximizing the benefits of DTF printing, acting as a game-changer for small businesses looking to optimize their production process. By allowing multiple designs to be printed on a single sheet, gang sheets significantly reduce both material costs and production time. This means that businesses can offer a versatile range of custom designs without stretching their resources too thin. As a result, gang sheets contribute to both operational efficiency and financial savings, making them an essential consideration for any DTF printing operation.

In addition to cost efficiency, gang sheets also facilitate a streamlined workflow. By organizing designs strategically on a single sheet, printers can execute printing jobs faster and with fewer interruptions. This not only speeds up order fulfillment but also enhances customer satisfaction with quicker turnaround times. As the DTF landscape continues to evolve, the strategic application of gang sheets remains a fundamental practice for successfully leveraging DTF printing techniques.

Mastering DTF Design Preparation

Effective DTF design preparation is crucial for achieving high-quality prints and maximizing material use. The design phase requires an understanding of how best to utilize the space on gang sheets without compromising the integrity of individual designs. Graphic design software such as Adobe Illustrator plays an integral role in this process, enabling creators to manipulate and position their artwork precisely. Designers must pay close attention to design size, spacing, and alignment, ensuring that each piece fits optimally within the sheet while leaving no unnecessary margins.

Furthermore, successful DTF design preparation involves meticulous attention to color management. By utilizing the correct color profiles and ensuring that colors are accurately represented, designers can prevent discrepancies between the screen and the final printed product. Investing time in the preparation stage guarantees that the DTF prints will display vibrant colors and crisp details, essential for meeting customer expectations and maintaining a competitive edge in the apparel market.

Choosing the Best Materials for DTF Printing

Selecting the right materials is integral to achieving optimal results in DTF printing. The quality of transfer films can greatly impact the vibrancy and durability of the printed designs. Using high-quality films ensures compatibility with the heat transfer process, leading to better adhesion and longer-lasting prints. Additionally, the choice of adhesive powders is just as crucial; the right powders enhance washability and ensure that designs withstand the rigors of everyday wear. By prioritizing high-caliber materials, printers set the foundation for successful DTF outputs.

Moreover, staying updated on the latest advancements in printing materials can offer a competitive advantage. With an increasing array of specialized films and alternative adhesive options on the market, printers can tailor their materials to suit various fabrics and design requirements. Experimenting with different combinations of materials can lead to unique finishes, further enhancing the creative potential of DTF printing for apparel.

Optimization of Printer Settings for DTF Success

The optimization of printer settings is a crucial element in achieving outstanding DTF print quality. Parameters such as temperature, speed, and ink selection must be fine-tuned to match specific materials and designs. Understanding the interaction between these settings can prevent common issues, such as insufficient adhesion or color bleed. By experimenting with different settings, printers can discover the ideal configurations that yield reliable, high-quality results.

In addition, regular maintenance of printing equipment ensures optimal performance. Dust and debris can accumulate within printers, which can affect print quality over time. By conducting routine checks and cleanings, printers can avoid potential malfunctions and maintain consistent output quality. This dedication to equipment upkeep not only enhances print integrity but also prolongs the life of the printing machinery, making it a smart investment for any DTF printing business.

Exploring Advanced DTF Techniques

After mastering the fundamentals of DTF printing, exploring advanced techniques can open up new creative possibilities. Layering designs is one such technique that adds depth and complexity to prints, enabling the creation of multifaceted visuals that stand out. Layering not only enhances the aesthetic appeal of printed items but also allows for innovative designs that capture consumer attention in a crowded marketplace.

Additionally, incorporating special effects into DTF printing can further differentiate your offerings. Techniques such as adding glitter, metallic finishes, or unique textures can result in striking designs that resonate with customers seeking something apart from traditional prints. As the demand for unique, customized apparel continues to rise, adopting advanced DTF techniques can provide businesses with a competitive edge, allowing for the creation of truly one-of-a-kind garments.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it function in DTF printing?

A DTF gangsheet builder is a tool or software that helps users create layouts for Direct-to-Film (DTF) printing by organizing multiple designs into a single transfer film sheet. This method optimizes material usage and time efficiency during the printing process, making it an essential aspect of DTF printing for apparel.

How can using gang sheets improve the efficiency of my DTF printing process?

Using gang sheets in DTF printing allows for the simultaneous printing of multiple designs on one sheet, which significantly reduces material waste and printing costs. This efficiency translates to faster turnaround times for orders, making it a beneficial strategy for businesses engaged in custom apparel.

What are the advantages of mastering advanced DTF techniques with gangsheet builders?

Mastering advanced DTF techniques, such as layering designs and applying special effects, can enhance the quality and creativity of prints produced using a gangsheet builder. By leveraging these techniques, you can create unique, eye-catching designs that stand out in the competitive apparel market.

What role does design preparation play in the effectiveness of a DTF gangsheet builder?

Design preparation is crucial when using a DTF gangsheet builder. Properly prepping your designs ensures they fit well on the sheet, avoids overlaps, and effectively utilizes the available space. This attention to detail results in high-quality prints and maximizes efficiency in the printing process.

How do I choose the right materials for my DTF gangsheet projects?

Choosing high-quality transfer films and adhesive powders is vital for successful DTF gangsheet projects. Opt for films that can withstand heat and ensure vibrant results, and select adhesives that promote durability, ensuring the final print adheres well and lasts through washes.

What best practices should I follow to maximize the quality of prints produced with a DTF gangsheet builder?

To maximize print quality with a DTF gangsheet builder, conduct regular maintenance on your printer, perform test runs to adjust designs, and gather feedback to refine your techniques. These best practices will help ensure longevity and optimal results in your DTF printing endeavors.

| Key Point | Description |

|---|---|

| Introduction | DTF printing combines technology and creativity, using gang sheets for efficient design transfer. |

| Understanding DTF Printing | DTF printing involves using special film to transfer vibrant designs onto various textiles. |

| Advantages of DTF Printing | Versatile, easy to use, and cost-effective for startups and small businesses. |

| Gang Sheets Definition | Layouts that allow multiple designs to be printed at once, optimizing efficiency. |

| Benefits of Gang Sheets | Save cost, time, and reduce material waste in printing. |

| Techniques for Building Gang Sheets | Includes design preparation, material selection, and printer optimization. |

| Recent Developments | Faster printing tech, eco-friendly inks, and user-friendly equipment. |

| Best Practices | Regular maintenance, testing prints, and adapting based on feedback. |

Summary

The DTF gangsheet builder is an innovative tool that not only enhances creative possibilities but also streamlines the printing process for businesses. Understanding the fundamentals of Direct-to-Film printing, mastering effective gang sheet design, and utilizing advanced techniques can significantly elevate your printing capabilities. As you delve deeper into this art, you’ll find that incorporating these strategies not only meets the demands of your clients but also helps your business thrive in a competitive environment. Stay informed with the latest advancements in DTF technology to ensure your processes remain efficient and your outputs are brilliant.