The DTF Gangsheet Builder is revolutionizing the way businesses approach Direct to Film printing, making the process more efficient and cost-effective. As you dive into the world of DTF, you’ll discover how this innovative tool can optimize your designs, enabling you to lay out multiple graphics on a single sheet and minimize material waste. By utilizing DTF printing tips alongside effective print optimization strategies, you can drastically enhance print quality and streamline your workflow. In this article, we will explore efficient printing techniques that empower you to make the most out of the DTF transfer process. Get ready to transform your printing experience and unlock the full potential of the DTF Gangsheet Builder for your business.

In the realm of Direct to Film printing, the term “gangsheet builder” refers to a powerful application that allows users to efficiently arrange various designs on a single film sheet, ultimately reducing waste and production costs. This approach not only enhances workflow efficiency but also capitalizes on the advantages of innovative ink and film technologies. By applying effective techniques designed for optimal design layouts, users can significantly improve their printing capabilities. Furthermore, understanding the nuances of the DTF transfer method can empower businesses to achieve superior results. Embracing the gangsheet builder concept opens new doors for print professionals seeking to maximize their operational efficiency and elevate their output quality.

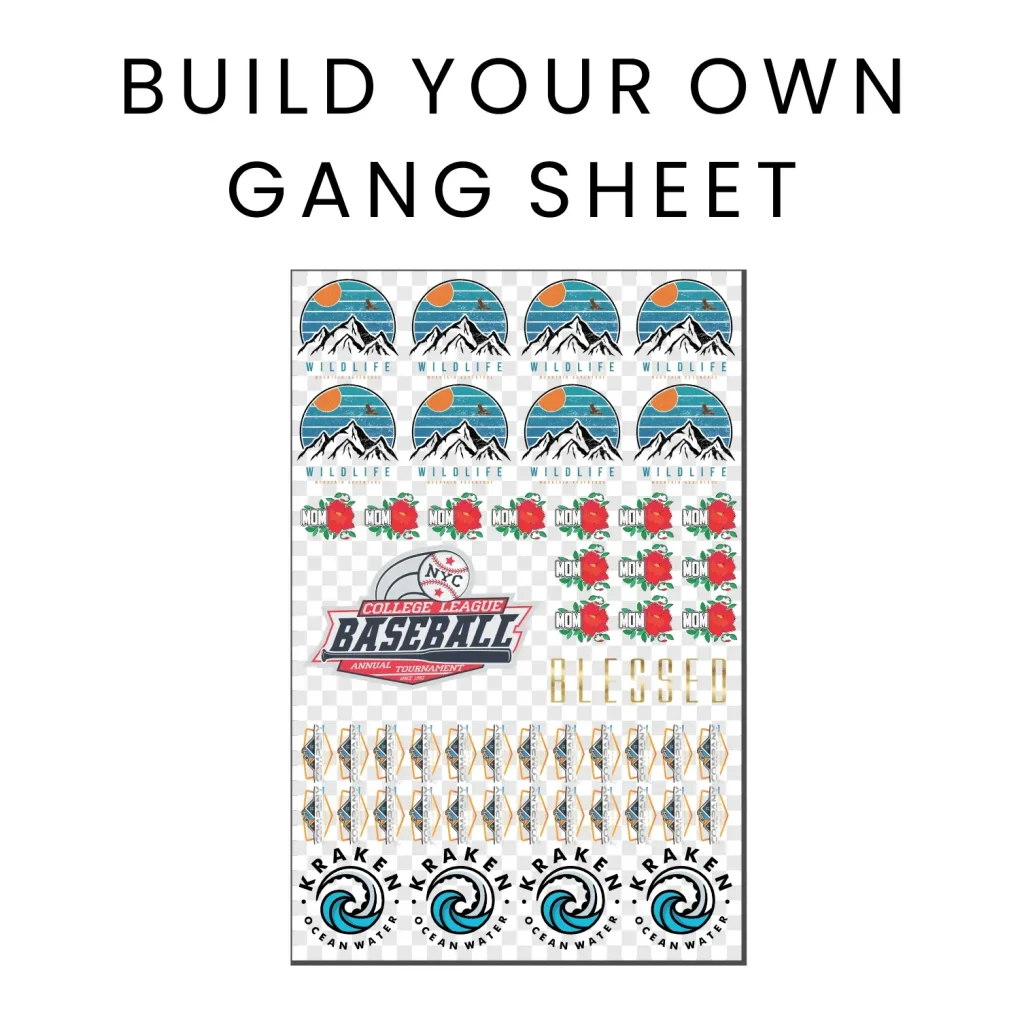

Maximizing Efficiency with DTF Gangsheet Builder

The DTF Gangsheet Builder is a revolutionary tool that aids DTF (Direct to Film) printing businesses in reducing material waste and enhancing productivity. This builder allows users to combine multiple designs into a single layout, effectively utilizing the available film and inks. One of the most critical advantages of using a gangsheet builder is that it reduces the overall cost per print by maximizing the number of designs that can be printed simultaneously. By understanding the functionalities of this tool, printers can integrate it seamlessly into their workflow, resulting in noticeable improvements in efficiency and output.

To leverage the benefits of the DTF Gangsheet Builder, it’s essential to familiarize yourself with its features. For starters, a well-optimized design layout can significantly reduce wasted space and materials. You should also explore different software options that enhance the creative process, enabling the user to arrange designs logically and visually appealingly. Furthermore, utilizing efficient printing techniques such as adjusting printer settings tailored to the DTF process ensures that users are achieving high-quality prints while maintaining speed in production. This layered understanding of the gangsheet builder will allow you to maximize its potential.

Best Practices for DTF Printing Tips

DTF printing, while straightforward, requires adherence to best practices for optimal outcomes. One of the foundational tips is to use high-quality materials that are specifically designed for DTF processes. From selecting the right types of film to identifying inks that yield vibrant colors, the material quality can make or break the print. Always research and choose reputable brands that align well with your printing objectives to ensure that each output maintains brilliance and durability through various applications.

Another essential tip in DTF printing is to focus on the design layout. A well-optimized design arrangement not only saves on material costs but also ensures that colors blend seamlessly across the prints. Avoiding overlap in your designs and grouping similar colors will reduce ink consumption and enhance the final product’s readability and aesthetic. Incorporating these design strategies into your workflow can significantly elevate your printing efficiency and the overall quality of your prints.

Navigating the Direct to Film Printing Process

The Direct to Film (DTF) printing process has gained popularity due to its versatility and high-quality results. Understanding all stages of DTF printing is vital – from the initial design setup to film transfer. Familiarizing yourself with the nuances of each step, such as ink load adjustments and curing methods, can expedite production while ensuring that each piece meets quality standards. As you navigate this process, remain adventurous by experimenting with various techniques and ink types, to discover what best enhances your specific prints.

Additionally, integrating print optimization strategies throughout the DTF process is crucial. For instance, using specialized curing techniques will ensure the longevity of the inks and the fidelity of colors post-transfer. Make sure to invest time in learning about different curing methods suited for various materials, as improper curing can lead to poor adhesion and print quality. Continuously monitoring these elements fosters a smoother workflow and ultimately results in superior printed products that stand out in a competitive market.

Essential Tips for Print Optimization Strategies

Print optimization strategies are essential for achieving high-quality results in DTF printing. Employing efficient techniques, like batching and adjusting ink loads, can streamline your production process and help reduce waste. For instance, batching similar designs together can save valuable production time while ensuring that print settings are consistently applied across multiple pieces. This not only enhances performance but also improves time management, creating a more efficient working environment.

Moreover, understanding the impact of different printer settings on print quality is crucial for optimization. Carefully calibrating color profiles and resolution settings allows for the reproduction of rich, vibrant prints that meet client expectations. Regularly revisiting and fine-tuning these settings will help to maintain consistency across print jobs, reducing the likelihood of unexpected issues and enhancing product quality. Remember, a well-optimized printing strategy is a blend of technical proficiency and creativity.

Exploring the DTF Transfer Process

The DTF transfer process involves several critical steps that must be executed with precision to achieve the desired results. After the design is printed onto a special film, it is coated with a powder adhesive that, once cured, allows for effective transfer onto the garment. Understanding the nuances of this process, such as the right temperatures and press times, is key to ensuring successful transfers without damaging the fabric or compromising print quality.

Additionally, experimenting with different fabrics can yield varying results in print fidelity and durability. Not all garments react the same way to the DTF transfer process, so it’s essential to test your methods on sample pieces before mass production. This experimentation not only aids in refining your technique but also expands the scope of services you can offer, ultimately enhancing customer satisfaction and expanding your client base.

Efficient Printing Techniques for DTF Success

Applying efficient printing techniques can significantly improve the results of your DTF printing endeavors. Techniques such as adjusting the speed and temperature settings on your printer, ensuring optimal ink flow, and maintaining printer cleanliness are paramount to continuous production. For example, adjusting the printer temperature can directly affect how the ink adheres to the film, ensuring that the end product is both vibrant and adheres well to fabrics. Such attention to detail fosters a more efficient workflow, ultimately resulting in higher-quality outputs.

Moreover, employing preventive maintenance on your printers can enhance longevity and efficiency. Regularly checking and cleaning print heads, nozzles, and alignment settings minimizes the risk of costly downtime due to malfunctions or print quality issues. Also, recording routine maintenance activities can provide insights into patterns that may arise, prompting proactive adjustments to your workflow. As a result, your overall efficiency in DTF processes will benefit from both better output quality and reduced production costs.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it improve DTF printing processes?

A DTF Gangsheet Builder is a tool that facilitates the layout of multiple designs on a single sheet in DTF (Direct to Film) printing. This method optimizes material usage, reduces waste, and speeds up production by allowing bulk printing, thus enhancing overall workflow efficiency.

What are some essential DTF printing tips when using a Gangsheet Builder?

Key DTF printing tips for using a Gangsheet Builder include optimizing design layouts to minimize waste, adjusting printer settings for resolution and color profiles, experimenting with ink loads for vibrant prints, and ensuring proper curing methods for effective adhesion.

How do I optimize the design layout in my DTF Gangsheet Builder?

To optimize designs in your DTF Gangsheet Builder, place your designs closely together without overlapping. Group similar colors to reduce ink usage and improve print quality, which is crucial for maximizing efficiency in the DTF printing process.

What printer settings should I adjust for efficient DTF printing?

When using a DTF Gangsheet Builder, adjust your printer settings for optimal quality by configuring resolution settings based on your printer’s capabilities and employing the correct color profiles. These adjustments help ensure accurate color reproduction in your prints.

What are effective print optimization strategies for DTF transfer processes?

Effective print optimization strategies in the DTF transfer process include using high-quality materials compatible with your gangsheet, experimenting with ink loads to find the right balance, and employing efficient curing methods, like adjustable heat press machines for better adhesion.

How can maintaining my equipment enhance the efficiency of DTF printing with a Gangsheet Builder?

Regular maintenance of your printing equipment ensures optimal performance by preventing issues such as clogging and misalignment. Cleaning printer heads, checking nozzles, and ensuring proper alignment reduce waste and enhance print quality, leading to greater efficiency in DTF printing.

| Key Point | Description |

|---|---|

| 1. Understand DTF Materials | Utilize high-quality materials compatible with your gangsheet for enhanced print quality. |

| 2. Optimize Design Layout | Arrange designs closely to minimize waste, and group similar colors to improve print efficiency. |

| 3. Adjust Printer Settings | Configure printer settings such as resolution and color profiles for optimal printing results. |

| 4. Experiment with Ink Loads | Test and find the right balance of ink to achieve vibrant prints without excess usage. |

| 5. Employ Efficient Curing Methods | Use adjustable heat press machines to ensure proper curing for different material types. |

| 6. Maintain Your Equipment | Regular maintenance checks on your printer can prevent breakdowns and improve performance. |

| 7. Batch Processing | Organize printing tasks in batches to save time and enhance efficiency during setup. |

| 8. Monitor Costs | Keep track of operational costs to adjust pricing strategies based on efficiency gains. |

Summary

DTF Gangsheet Builder is a powerful tool that can significantly enhance your printing process by allowing for the efficient layout of multiple designs. By adhering to best practices such as understanding the materials, optimizing layouts, properly configuring printer settings, and maintaining equipment, users can achieve vibrant prints while minimizing waste and costs. Implementing these strategies not only improves productivity but also ensures high-quality output that stands out. Embrace the potential of the DTF Gangsheet Builder to elevate your printing business and maximize operational efficiency!