DTF printing technology, or Direct to Film printing, is transforming the custom printing world, bringing unprecedented efficiency and precision to various industries, especially in textile applications. This innovative process allows designers to transfer vibrant, high-quality prints onto fabrics through heat and pressure, revolutionizing how businesses approach custom apparel and promotional items. With an emphasis on sustainability, DTF printing is becoming increasingly popular due to its use of eco-friendly materials, including water-based inks and recyclable films. As we explore the many benefits and applications of DTF printing technology, it’s clear that it is not only redefining creativity in textile printing but also supporting the shift towards more sustainable practices in the industry. Join us as we dive into the endless possibilities this remarkable printing method offers for enhancing your brand and product visibility.

Also known as Direct to Film printing, this cutting-edge technique is becoming a go-to solution for businesses seeking bespoke printing solutions. By enabling detailed designs to be transferred seamlessly onto various surfaces, DTF printing is at the forefront of textile printing innovations. This approach caters not only to the clothing sector but also finds applications in home textiles and promotional products. With its eco-conscious practices and user-friendly technology, this method is paving the way for businesses aiming to integrate sustainable printing into their operations. Discover how DTF technology is reshaping the landscape of custom apparel and creating new opportunities across diverse industries.

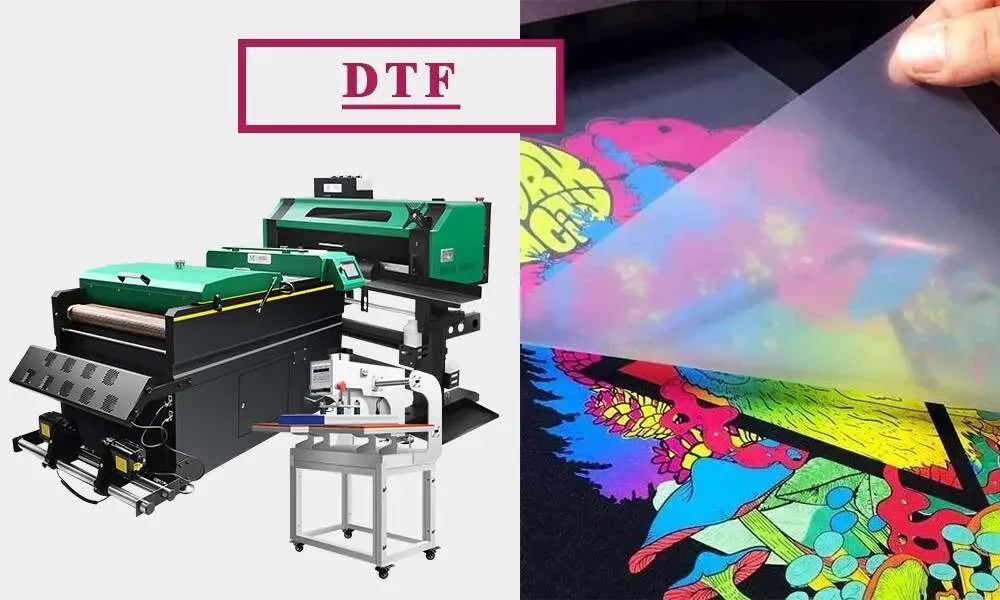

Understanding DTF Printing Technology

Direct to Film (DTF) printing technology is an innovative printing method transforming the custom apparel industry. This technique leverages the power of advanced printing machines to apply intricate designs on specially coated film. The process begins with printing a design on this film, followed by a powder adhesive application. Once heat and pressure are applied, the design is seamlessly transferred onto various materials, showcasing vibrant colors and fine details.

One of the major selling points of DTF printing is its versatility across different textiles. Whether it’s applying graphics on cotton, polyester, or blends, the adaptability of DTF ensures that businesses can cater to diverse market needs. As a result, DTF printing is not only revolutionizing custom apparel but also paving the way for fresh opportunities in sectors such as promotional items and home textiles.

Diverse Applications of DTF Printing

DTF printing technology is remarkably versatile, making it suitable for a wide range of applications beyond traditional clothing. Businesses can utilize DTF for producing custom items like bags, hats, and even interior decor textiles. This opens new revenue streams for companies looking to diversify their product offerings and tap into the growing demand for personalized goods.

Moreover, the customization potential of DTF printing is particularly appealing to promotional companies. Creating branded items tailored to specific events or public relations strategies can enhance customer engagement. With DTF’s capability to deliver high-quality prints on an array of substrates, companies can maintain a competitive edge in the market.

Eco-Friendly Practices in DTF Printing

As sustainability becomes a critical consideration in manufacturing, DTF printing technology meets this demand head-on. By utilizing water-based inks and recyclable films, DTF significantly reduces the environmental impact commonly associated with conventional printing methods. This eco-friendly shift not only appeals to consumers increasingly concerned about sustainability but also aligns businesses with current ecological trends.

Promoting a greener approach, DTF printing can dramatically lower waste, especially in industries that practice on-demand printing. This model counters the trend of excessive inventory and waste while affirming a commitment to responsible production. Businesses that embrace these sustainable practices not only attract eco-conscious customers but also foster loyalty in a market that values environmental stewardship.

Advancements in DTF Printing Technology

Recent advancements in DTF printing technology have improved printer performance and overall quality significantly. Manufacturers are now offering printers with higher resolutions, which allows for sharper, more intricate designs. These enhancements facilitate a smoother workflow, allowing businesses to scale up production more efficiently while maintaining exceptional quality standards.

Furthermore, user-friendly interfaces and automated features make DTF technology accessible, even to novices. These improvements mean that even small businesses can produce professional-grade prints without necessitating extensive training or expertise. As technology continues to evolve, so too will the possibilities within the realm of DTF printing.

High-Quality Output with DTF Printing

One of the standout benefits of DTF printing is the quality and durability of the final product. Designs produced through this method maintain their vibrancy and integrity through multiple washes, ensuring that customer satisfaction remains high over time. This durability is a crucial selling point, particularly for businesses focusing on apparel and promotional items where wear and tear can be a concern.

Moreover, the softness of the prints enhances the overall feel of the fabric, making it a preferred choice among consumers who prioritize comfort along with style. The technology eliminates the stiff feel that may be associated with other printing methods, ensuring that garments not only look good but also feel good.

Cost-Effectiveness of DTF Printing

For businesses, cost-effectiveness is paramount, and DTF printing delivers on this front remarkably well. The demand for customized products typically comes with higher manufacturing costs; however, DTF’s efficiency minimizes waste through on-demand printing capabilities. This not only reduces overhead but also allows entrepreneurs to offer competitive pricing.

Additionally, the streamlined process associated with DTF helps in maximizing profit margins. With the ability to cater to small orders without compromising on quality, small businesses can thrive in niche markets, meeting specific client needs while avoiding unnecessary bulk production.

Frequently Asked Questions

What is the process involved in DTF printing technology?

DTF printing technology involves printing a design on a special film, applying a powder adhesive, and then using heat and pressure to transfer the design onto fabrics. This method ensures vibrant designs that are both durable and soft to touch, making it ideal for custom apparel and textiles.

How does DTF printing compare to traditional textile printing methods?

Unlike traditional textile printing methods such as screen printing, DTF printing offers superior detail and color vibrancy while being more cost-effective for small runs. It allows for on-demand production, which minimizes waste and enhances profitability for businesses in the custom apparel sector.

What are the primary applications of DTF printing technology?

DTF printing technology is highly versatile, being used in various applications including custom clothing, promotional items, and home textiles. Its ability to print on a wide range of fabrics and colors makes it a popular choice for creating unique products in these sectors.

What advancements have been made in DTF printing technology recently?

Recent advancements in DTF printing technology include improved printer performance with higher resolutions, faster production speeds, and user-friendly interfaces. These innovations enhance print quality and make the technology accessible for new users in the custom apparel market.

Is DTF printing technology a sustainable printing option?

Yes, DTF printing technology is considered a sustainable printing option as it utilizes water-based inks and recyclable films. This eco-friendly approach significantly reduces the environmental impact associated with traditional printing methods, appealing to environmentally conscious consumers.

What are the main benefits of adopting DTF printing applications in a business?

Adopting DTF printing applications provides numerous benefits, including high-quality and durable prints, cost-effectiveness for small runs, and ease of use due to technological advancements. These advantages make DTF printing an attractive solution for businesses looking to innovate in custom apparel and promotional materials.

| Aspect | Details |

|---|---|

| Definition | Direct to Film (DTF) printing technology is a modern technique for transferring designs onto fabrics using heat and pressure. |

| Process | Designs are printed on a specialized film, treated with adhesive, and heat-pressed onto the fabric. |

| Market Adoption | DTF printing is becoming popular among small to medium-sized businesses due to its cost-effectiveness and the ability to do on-demand printing. |

| Sustainability | Uses water-based inks and recyclable films to reduce ecological impact. |

| Applications | Widely used in clothing, promotional items, and home textiles. |

| Key Benefits | High quality, durability, cost-effectiveness, and user-friendly technology. |

Summary

DTF printing technology is revolutionizing the custom printing landscape by offering versatile solutions for various industries. This innovative method allows intricate designs to be transferred onto fabrics with ease, enhancing the quality of custom apparel and promotional items. With continuous advancements in technology that improve printer performance and a focus on sustainability, DTF printing is not only effective but also aligns with environmentally conscious practices. As businesses increasingly adopt this technology, the custom printing industry is poised for a substantial transformation, providing exciting opportunities for growth and creativity.