When it comes to garment printing, understanding **DTF transfer by size** is crucial for achieving high-quality results. This innovative Direct-to-Film (DTF) printing process provides significant advantages, allowing for custom DTF transfers that meet a variety of customer needs. As businesses and DIY enthusiasts delve into the world of DTF printing, awareness of size considerations in printing is essential for optimizing both design and application. The ability to produce high-resolution prints, regardless of size, showcases the versatility of DTF transfer techniques, making it a favored solution for modern decorators. In this article, we will explore the implications of transfer size, its effect on print quality, and key tips to maximize the benefits of DTF printing in your projects.

In the realm of fabric decoration, grasping the concept of **size-based DTF transfers** is essential for anyone looking to deliver quality results. This printing method not only enhances the visual appeal of garments but also presents a range of options for varying design requirements, tailored specifically to different fabric sizes. By examining how dimensions influence the transfer process, businesses can better grasp shift dynamics between smaller motifs and larger graphics. Understanding the nuances of size adaptability allows print service providers to fully leverage the capabilities of DTF printing, aligning with client needs while ensuring optimal quality. Explore with us how size variations and corresponding strategies can significantly impact your custom printing endeavors.

Comprehensive Guide to DTF Printing Techniques

When exploring DTF printing techniques, it’s essential to recognize that the method allows for incredible versatility in design application. DTF printing employs a specialized film that retains ink quality while offering a broad range of transfer sizes. This technology is particularly beneficial for creatives looking to print complex images because it supports intricate detail and vibrant colors. By utilizing the right DTF transfer techniques, businesses can produce high-quality prints that make a statement, enhancing the visual appeal of garments.

Moreover, there are various techniques within DTF printing that can optimize production processes. One notable method is the use of dual-layer transfers, which can add depth and texture to designs. This technique is especially effective for larger transfers, making use of the printed film’s capacity to handle detailed graphics without losing resolution. As the market for DTF printing evolves, embracing innovative techniques becomes crucial for staying competitive and meeting customer expectations.

Maximizing Print Quality with Size Considerations

Understanding the importance of size considerations is fundamental for achieving optimal print quality in DTF transfers. Smaller designs, for instance, require higher DPI settings during printing to ensure the final product is crisp and vibrant. These high-resolution outputs are important for designs that include fine details, logos, or text. Conversely, when working with larger transfers, the DPI may be adjusted lower, allowing for high-quality prints that maintain their clarity even across wider surfaces, such as t-shirts or hoodies.

Additionally, the choice of material plays a significant role in the overall print quality linked to transfer size. Some fabrics react better to larger DTF transfers, providing a smooth application surface that helps the transfer adhere properly. Thus, understanding size-related material adaptability can lead to enhanced durability and resistance, ensuring that prints not only look good on arrival but stands the test of time through washes and wear.

Cost-Efficiency in DTF Printing by Size

Exploring the relationship between size and cost is vital for those engaged in DTF printing. Production costs can vary significantly depending on the size of the transfers being created. While smaller transfers may seem less expensive, they can also include additional labor costs since numerous small prints might be required for larger orders, ultimately driving costs up. On the other hand, larger DTF transfers can leverage economies of scale, thus reducing the per-unit cost.

It’s important for businesses to develop effective pricing strategies aligned with their production size. By analyzing the cost structures related to DTF printing, companies can optimize their offerings and maintain competitive pricing. This economic sensitivity not only aids in achieving higher profit margins but also ensures that businesses can cater to diverse customer demands while providing high-quality services.

Innovative Materials for DTF Transfers

The choice of materials used for DTF transfers has a significant influence on both the application process and the quality of the final product. Advanced fabrics tailored for DTF printing can support a wide range of transfer sizes while allowing vibrant colors to emerge. For instance, using polyester blends or cotton provides great adherence and durability, making them ideal for larger prints that demand stronger bonding capabilities.

Moreover, there are exciting developments in eco-friendly materials that suit DTF printing needs, appealing to a growing market of environmentally-conscious consumers. These materials not only complement the DTF printing process but also enable businesses to highlight their sustainable practices, further enhancing brand image. As the DTF printing sector evolves, staying updated on material innovations will be crucial for achieving superior results across different transfer sizes.

Custom DTF Transfers: Tailoring to Your Needs

Custom DTF transfers offer flexibility that accommodates various design needs, empowering businesses and individuals alike to express their creativity. The ability to customize size is particularly advantageous in creating unique apparel or promotional products tailored to specific audiences. From small stickers to sizable graphic designs for team jerseys, custom DTF transfers enable precise control over aesthetics and impact.

Furthermore, the concept of custom DTF transfers expands into various industries, ranging from fashion to merchandising. For instance, small businesses can leverage personalized transfers to release limited edition merchandise that resonates with fans and customers, driving engagement and sales. By investing in custom DTF solutions that cater to varied sizes, brands can stand out in a crowded market, creating a lasting impression that builds customer loyalty.

Future Trends in DTF Transfers and Size Adaptations

As the direct-to-film printing industry continues to grow, new trends are emerging that will redefine how size impacts DTF transfers. For example, advancements in printing technology are leading to the development of faster printing devices capable of producing larger transfers efficiently without sacrificing quality. This trend represents a substantial leap forward, enabling businesses to keep pace with increasing demand for personalized apparel.

Additionally, the move towards digitization in the printing sector fosters greater customization options and on-demand printing by size. This could drastically change supply chain dynamics, as businesses can print transfers as required, minimizing excess inventory while ensuring immediate responsiveness to market trends. The evolution of DTF printing techniques and size considerations will likely shape the future of garment printing, paving the way for innovative practices and increased profitability.

Frequently Asked Questions

What are the key size considerations in DTF transfer printing?

When utilizing DTF transfer by size, important considerations include the required resolution for different sizes, material compatibility, and the adaptability of heat settings on machines. Smaller designs generally require a higher DPI for clarity, while larger prints may necessitate adjustments for adhesion and durability.

How does the size of DTF transfers affect print quality?

The size of DTF transfers significantly influences print quality. Smaller designs should utilize higher DPI settings to capture intricate details effectively, whereas larger transfers can often use lower DPI without sacrificing quality. Balancing size with clarity is crucial to ensuring aesthetically pleasing results.

Can DTF transfer techniques accommodate various garment sizes?

Yes, DTF transfer techniques are highly versatile and can accommodate a variety of garment sizes. Whether creating small logos for shirts or large graphics for hoodies, DTF printing allows for flexibility in transfer sizes while maintaining high-quality results.

What are the advantages of using DTF printing for different size transfers?

The advantages of DTF printing for various transfer sizes include versatility, efficiency in producing intricate designs, and the ability to adapt to different materials. DTF transfers can be created for small promotional items or large apparel graphics, making them a favored choice across the printing industry.

How do machine settings change based on DTF transfer size?

Machine settings for DTF transfers must be adjusted based on size. Larger transfers typically require specific heat, pressure, and time settings to ensure proper adhesion and avoid damage. Proper configuration enhances production efficiency and minimizes the risk of errors or defects.

What economic factors should businesses consider with DTF transfer by size?

When evaluating DTF transfer by size, businesses should consider material costs, labor, and processing expenses. Larger transfers might incur higher production costs, while smaller transfers can be mass-produced economically. Understanding these factors will aid businesses in optimizing pricing strategies for profitability.

| Key Point | Description |

|---|---|

| Understanding DTF Transfers | DTF transfers use a specialized film and advanced ink technology for high-quality fabric prints. |

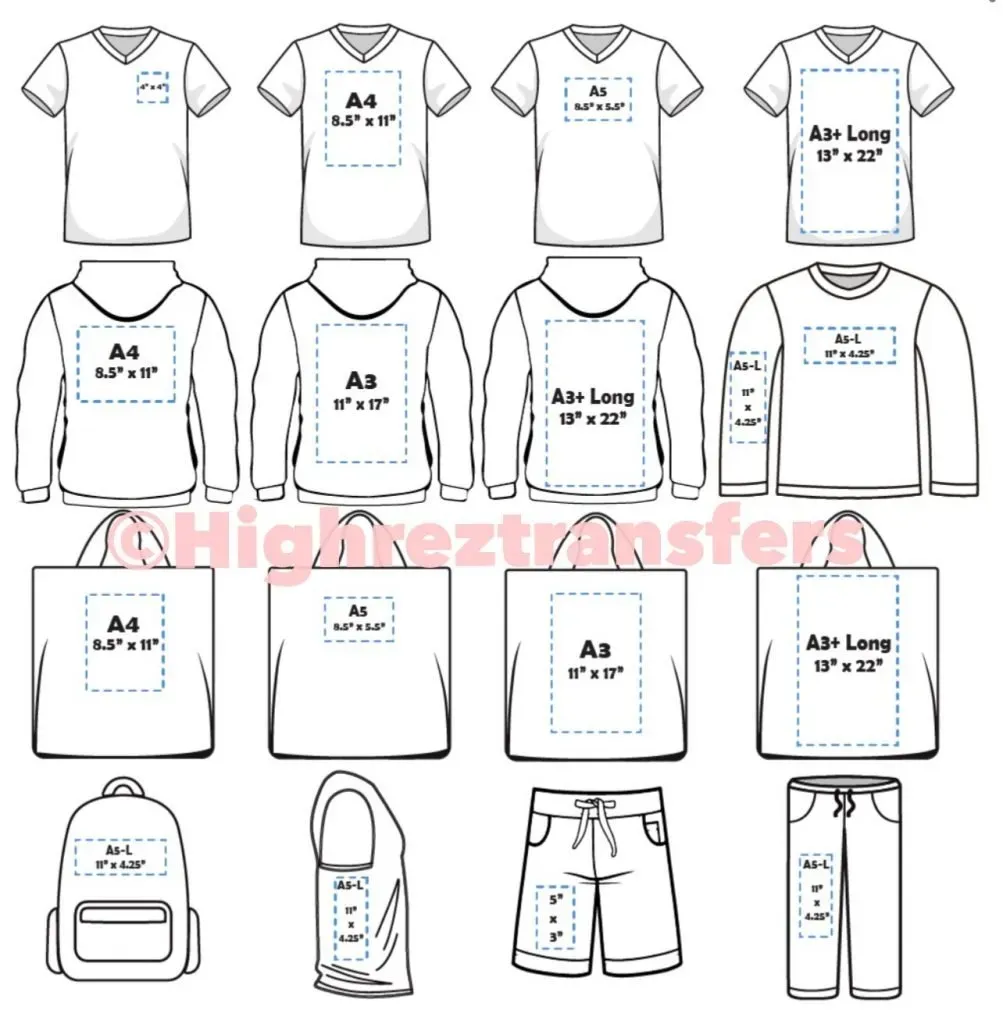

| Variability in Sizing Options | DTF technology offers a wide range of sizes, accommodating both small logos and large graphics. |

| Print Quality Issues by Size | Smaller designs require higher DPI for clarity, while larger designs can use lower DPI settings. |

| Material Adaptability | Different materials handle various sizes differently, affecting adherence and durability. |

| Machine Configuration Adjustments | Larger transfers need specific machine settings to optimally adhere without damaging the garment. |

| Cost-Effective Production | Size impacts material and labor costs, affecting pricing strategies for print production. |

| Innovations and Trends | Eco-friendly inks and market expansion are shaping DTF printing practices by size. |

Summary

DTF transfer by size is a pivotal aspect of the garment printing process, influencing quality, compatibility, and profitability in custom designs. The versatility of DTF technology allows for a range of sizes, enabling businesses to meet diverse customer needs effectively. As understanding size impacts every dimension of DTF transfers, from print quality and material selection to machine adjustments, businesses must stay informed about emerging trends and technologies. This knowledge not only enhances production efficiency but also ensures high customer satisfaction and competitive advantage in the market.