UV DTF transfer materials have revolutionized custom printing by integrating the best DTF materials with state-of-the-art UV printing supplies. This innovative method allows for the production of durable prints that maintain their vibrancy across a diverse range of substrates, from textiles to hard goods. By utilizing high-quality transfer films, printers can achieve professional results that stand up to wear and tear, making them ideal for both personal and commercial applications. The ongoing advancements in professional printing techniques make understanding these materials essential for anyone looking to elevate their print game. In this guide, we will delve deeper into the key components and best practices that will help you harness the full potential of UV DTF transfer technology.

Direct to Film (DTF) transfer materials, particularly those that utilize UV technology, are making a significant impact in the printing landscape. This approach merges innovative printing techniques with specialized films to create high-resolution, vibrant designs on numerous surfaces. Whether you’re seeking robust options for textiles or durable finishes for hard goods, understanding the various types of DTF transfer films available is critical. As the demand for customized solutions grows, these cutting-edge materials are at the forefront, enabling printers to deliver unique and visually stunning products. In this discussion, we will explore the essential aspects of selecting the right DTF materials and how they contribute to lasting print quality.

Understanding UV DTF Transfer Technology

UV DTF transfer technology is an innovative approach that combines the speed of UV printing with the versatility of direct-to-film applications. This fusion not only amplifies the color vibrancy of prints but also ensures that they can be reliably transferred onto diverse substrates, from textiles to hard surfaces. This technology offers a solution for businesses looking to push creative boundaries and deliver products that stand out in the market. Understanding how UV DTF works is essential for any professional aiming to harness its full potential.

The core of UV DTF printing lies in its unique application process, which utilizes UV inks that are cured instantly with ultraviolet light. This advancement allows for rapid production times without compromising quality. For professionals in the printing field, knowledge of both the technology and the best UV DTF transfer materials available can significantly impact their overall output quality and efficiency.

The Best UV DTF Transfer Materials for Professional Results

When it comes to achieving the highest quality prints in UV DTF transfer, the selection of materials is pivotal. The best DTF materials not only include high-performance transfer films but also inks and adhesives that enhance the overall printing process. For instance, well-known brands like DuraTrans and Avery Dennison provide films that are engineered to maximize compatibility with UV inks, ensuring strong adhesion and longevity in the final print. For those in the printing industry, identifying and utilizing these materials effectively can lead to superior product outputs.

In addition to transfer films, the choice of inks plays a significant role in the final appearance of prints. UV inks from reliable manufacturers like Mimaki and Epson are celebrated for their vibrant color reproduction and durability against wear and tear. By investing in high-quality inks and adhering to best practices, printing professionals can create not only aesthetically pleasing designs but also durable prints that satisfy the demands of the end-users.

Essential Best Practices for UV DTF Printing

Mastering UV DTF printing requires a deep understanding of best practices that ensure optimal results. One of the key elements is printer calibration, as an accurately calibrated printer can significantly reduce errors and improve color consistency. This practice becomes essential when working with various transfer films and inks, as each material may have its own specific requirements that need to be addressed for the best results.

Another critical aspect is the settings on the heat press. Professionals should pay meticulous attention to temperature and pressure settings to avoid issues like poor adhesion or bubbles in the print. Proper preparation of the substrate before applying the transfer is equally important; cleaning surfaces ensures that no foreign particles interfere with the printing process, facilitating a smooth and consistent transfer of design.

Emerging Trends in UV DTF Printing for 2023

Keeping abreast of technology trends is vital for success in the UV DTF printing world. A notable trend gaining momentum is the shift towards eco-friendly materials, with manufacturers focusing on sustainable inks and films. This green initiative not only lessens environmental impact but also appeals to consumers who are increasingly aware of sustainability while purchasing products. Moving forward, integrating eco-friendly practices can position businesses favorably in a competitive market.

Additionally, the advent of automation in UV DTF printing is revolutionizing how businesses operate. By streamlining processes and minimizing manual errors, automation enhances productivity and quality, allowing printing professionals to deliver consistent results at a faster pace. Harnessing these trends is essential for staying competitive, as consumers continue to seek personalized and innovative products.

Comparing UV DTF and Traditional Printing Methods

When comparing UV DTF printing with traditional printing techniques, the differences in output and capabilities are striking. Unlike conventional methods, UV DTF allows for printing on a wider array of substrates, including materials typically deemed unsuitable for standard ink applications. This flexibility not only expands creative possibilities but also opens up new markets for businesses looking to diversify their product offerings.

Moreover, the immediate curing process associated with UV inks provides an advantage in handling and production times. Traditional methods often require longer drying times, potentially delaying project completion. This efficiency can lead to increased throughput, making UV DTF a more appealing option for businesses aiming for speed without sacrificing quality.

Tips for Selecting the Right UV DTF Transfer Films

Choosing the right transfer film is crucial for successful UV DTF printing, as the quality of the film can directly impact print durability and vibrancy. Professionals should look for films that are specifically designed to work with UV inks, ensuring compatibility and optimal adhesion. Key things to consider include the thickness of the film, its coating, and how well it performs under different heat and pressure conditions.

It’s also essential to read product reviews and seek recommendations from industry peers when selecting transfer films. By investing time in choosing the most suitable films and experimenting with different brands, printers can capitalize on the unique qualities of their chosen materials, ultimately leading to better print outcomes and satisfied clients.

Frequently Asked Questions

What are the best UV DTF transfer materials for vibrant prints?

When selecting the best UV DTF transfer materials, look for high-quality transfer films like DuraTrans or Avery Dennison DTF Film, alongside durable UV inks such as Mimaki Uvijet and Epson SureColor. These materials ensure excellent adhesion and vibrant colors that last.

How does UV DTF printing enhance professional printing techniques?

UV DTF printing enhances professional printing techniques by allowing for immediate handling of prints through UV inks that cure under ultraviolet light. This technique not only improves durability but also supports high-quality finishes on various substrates, making it a standout in the printing industry.

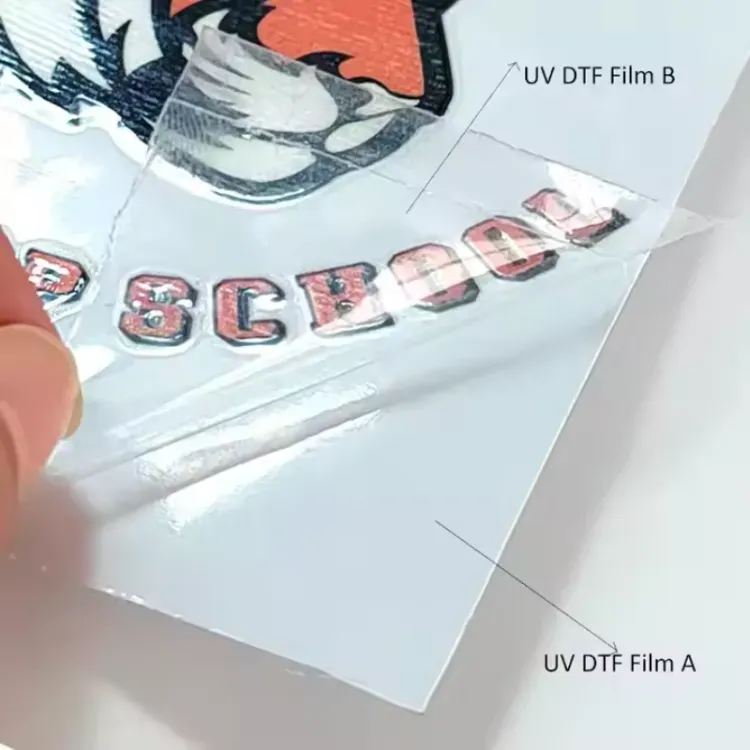

What role do transfer films play in UV DTF printing?

Transfer films are crucial in UV DTF printing as they provide a medium for applying UV inks. High-quality films like DuraTrans ensure smooth transfers and strong adhesion, resulting in durable prints that maintain vibrant colors even after washing.

Are UV inks essential for achieving durable prints with UV DTF materials?

Yes, selecting the right UV inks is essential for achieving durable prints with UV DTF materials. Inks like Mimaki Uvijet are known for their color fidelity and strong adhesion, ensuring that your prints remain vibrant and withstand everyday wear.

How do adhesives affect the quality of UV DTF transfers?

Adhesives significantly influence the quality of UV DTF transfers. Using high-quality adhesives like Siser EasyWeed ensures reliable bonding to various surfaces, which helps maintain the integrity of your designs through washing and regular use.

What are emerging trends in UV DTF printing to watch in 2023?

In 2023, notable trends in UV DTF printing include a focus on eco-friendly innovations and sustainability, advancements in automation for consistent results, and an increasing demand for customization and personalization of prints to cater to consumer preferences.

| Key Aspects | Details |

|---|---|

| Introduction to UV DTF Transfer Technology | A unique printing technology combining UV printing with transfer techniques for vibrant prints on diverse substrates. |

| What is UV DTF Printing? | Involves printing designs on special transfer films with UV inks cured with UV light, enhancing durability and versatility on materials like plastics and metals. |

| Top UV DTF Transfer Materials | – Transfer Films: DuraTrans, Avery Dennison DTF Film – Inks: Mimaki Uvijet, Epson SureColor – Adhesives: Siser EasyWeed, Thermoflex Plus |

| Best Practices | – Ensure proper printer calibration. – Adjust heat press settings correctly. – Clean substrates before application. |

| Emerging Trends | – Eco-friendly innovations in materials. – Increased automation in printing processes. – Rising demand for customization and personalization. |

Summary

UV DTF Transfer Materials are essential for achieving exceptional results in custom printing. This versatile technology not only enhances the quality and vibrancy of prints but also allows for applications on a wide range of substrates. By selecting superior transfer films, inks, and adhesives, and adhering to best practices, professionals can create durable and eye-catching prints. Moreover, staying updated with emerging trends like eco-friendly practices and increased automation will further enhance your capabilities in this dynamic industry. Understanding these key elements will ensure success in the world of UV DTF printing.