UV DTF transfer technology is transforming the landscape of fabric printing by offering unmatched efficiency and high-quality results. As this advanced fabric printing technology gains popularity, it stands out with its eco-friendly practices and precision in customized designs. Businesses in the textile industry are now leveraging the numerous UV printing advantages, including rapid production speeds and reduced waste, making it a sustainable option. With the demand for custom fabric prints on the rise, UV DTF transfer proves to be an innovative solution that meets the diverse needs of brands and consumers alike. This blog post will delve into the compelling benefits of UV DTF transfer, providing insights into its applications and future potential in the fabric printing market.

Direct to Film transfer, commonly known as DTF transfer, is an innovative technique in the realm of fabric printing that focuses on delivering exceptional quality and versatility. This method allows for high-resolution printing on a variety of fabrics, effectively catering to the growing market for unique and personalized fabric products. As the industry embraces advancements in UV printing technology, businesses are becoming increasingly aware of the benefits that come with this method, such as its eco-friendly nature and rapid production capabilities. By adopting DTF transfer technology, companies can meet the demand for high-quality fabric transfer solutions while effectively reducing their environmental footprint. This exploration of DTF printing will highlight its advantages, applications, and the future it holds in the textile industry.

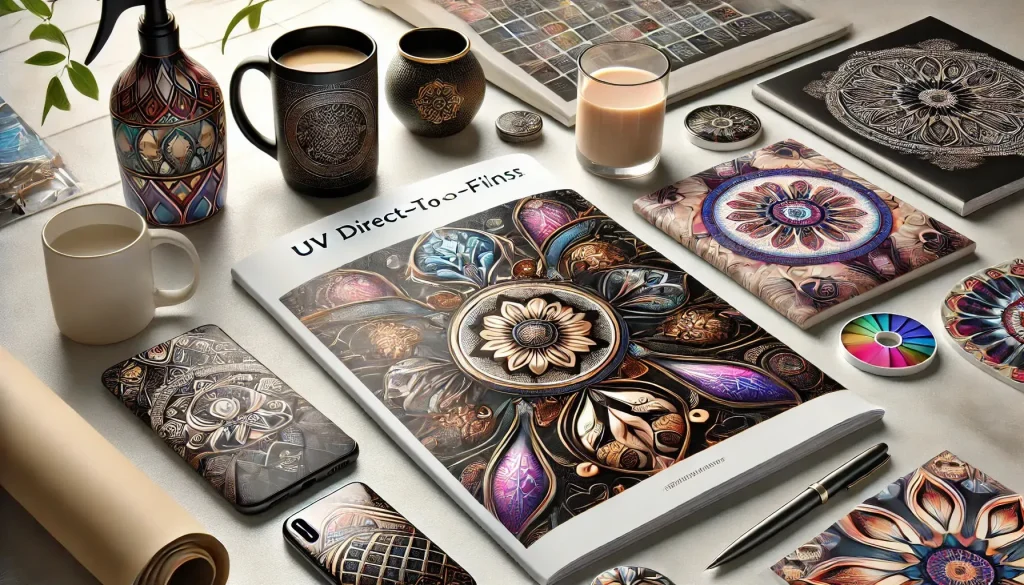

Understanding UV DTF Transfer Technology

UV DTF transfer technology combines advanced UV printing techniques with direct-to-film processes, creating a method that ensures vibrant, long-lasting prints. This innovation allows for intricate designs to be replicated with precision, facilitating a high-quality output that is essential for competitive fabric printing. As this technology evolves, businesses are increasingly leveraging its capabilities for various applications, from custom fabric prints to promotional merchandise.

The significance of UV DTF transfer lies in its ability to adapt to numerous substrates, making it a versatile solution in the printing industry. Whether you’re looking at fabric, metal, or even plastic, this technology impressively caters to a wide array of materials. Its flexibility opens doors for custom projects, allowing your business to diversify its offerings and stay ahead in the fabric printing market.

The Eco-Friendly Benefits of UV DTF Printing

One of the standout advantages of UV DTF transfer technology is its eco-friendly attributes. Utilizing inks that contain fewer harmful solvents compared to traditional fabric printing methods significantly lowers the ecological impact associated with the production process. Brands that prioritize sustainability can benefit from adopting UV DTF technology, which aligns with the growing consumer demand for greener practices in fabric printing.

Moreover, UV DTF transfer manufacturers are committing to reducing their environmental footprint by developing inks and materials that are less harmful. This shift toward eco-friendly fabric printing not only caters to the environmentally-conscious market but also enhances the brand’s image and reputation. By making the transition to UV DTF, businesses can actively contribute to a more sustainable manufacturing ecosystem.

…

…

Frequently Asked Questions

What are the main advantages of using UV DTF transfer in fabric printing?

UV DTF transfer offers several advantages, including high-quality and detailed prints, quick turnaround times, and eco-friendly inks that reduce environmental impact. This technology allows for versatile applications on various substrates, ensuring vibrant colors and durability for custom fabric prints.

How does UV DTF transfer compare to traditional printing methods?

Unlike traditional printing methods, UV DTF transfer utilizes UV light to cure inks instantly, resulting in sharper details and brighter colors. Additionally, it provides faster production times and greater adaptability across materials, making it an efficient alternative for fabric printing technology.

Is UV DTF transfer an eco-friendly fabric printing option?

Yes, UV DTF transfer is considered an eco-friendly fabric printing technology. The inks used in this process contain fewer harmful solvents compared to conventional inks, which helps reduce the overall ecological footprint, appealing to businesses aiming for sustainable production methods.

Can UV DTF transfer be used for custom fabric prints?

Absolutely! UV DTF transfer is ideal for custom fabric prints, allowing businesses to create unique and personalized designs with a vast color range and finishes, such as metallic or fluorescent options, catering to modern consumer demands for customization.

What types of surfaces can UV DTF transfer technology print on?

UV DTF transfer technology is versatile and can print not only on fabrics but also on various materials such as metal, glass, and plastic. This broad application range makes it an attractive option for businesses involved in promotional items and home décor.

How does the durability of UV DTF prints compare to other fabric printing techniques?

UV DTF prints are highly durable, exhibiting excellent resistance to scratches, fading, and cracking. This durability is achieved through the UV curing process, making UV DTF particularly suitable for high-wear products like sports apparel, ensuring long-lasting quality.

| Key Advantages | Details |

|---|---|

| High Quality and Detail | Produces high-resolution designs with vibrant colors and durability. |

| Versatility in Applications | Adapts to fabrics, metal, glass, and plastic, enhancing market opportunities. |

| Quick Turnaround Time | Fast printing processes for large orders, suitable for custom requests. |

| Eco-Friendly Options | Uses inks with fewer harmful solvents, appealing to eco-conscious consumers. |

| Cost Efficiency | Long-term savings from reduced waste and quicker production times. |

| Durability | Excellent resistance to scratching, fading, and cracking for high-wear applications. |

| Customization and Color Range | Supports various colors and finishes for unique, personalized products. |

Summary

UV DTF transfer technology is revolutionizing the fabric printing industry with its numerous advantages, including high-quality output, exceptional versatility, and increased cost efficiency. By allowing printers to achieve vibrancy and durability across a range of materials, UV DTF has quickly become essential for businesses looking to enhance their product offerings. As the market shifts towards personalized and eco-friendly options, the demand for UV DTF transfer is likely to grow, setting new standards for quality and performance in fabric printing. With ongoing advancements pushing the limits of what is possible with this innovative technology, UV DTF transfer will continue to shape the future of the printing landscape.